Weld Mount SS Stud – Reliable or Risky for Marine?

Weld Mount 1.50″ Tall 1/4 x 20 ST125-1420-24SS SS Stud 1.25″ Base 10 Pack for Boats & Marine Engines

Introduction

If you’re looking for a robust and corrosion-resistant fastener solution for your boat or marine engine, the Weld Mount 1.50″ Tall 1/4 x 20 ST125-1420-24SS SS Stud 1.25″ Base 10 Pack is engineered to outperform traditional mounting systems. This reliable stud system is part of the high-performance Weld Mount series that eliminates the need for drilling, welding, or mechanical fasteners that compromise hull integrity. Perfect for marine electricians, DIY boat owners, and professional riggers alike, this stud is designed to stand up to the harshest sea conditions. Whether you’re mounting electrical boxes, cable clamps, or hydraulic components, the Weld Mount SS Stud delivers unmatched reliability and versatility in a compact, easy-to-install format.

Overview / What Is Weld Mount SS Stud

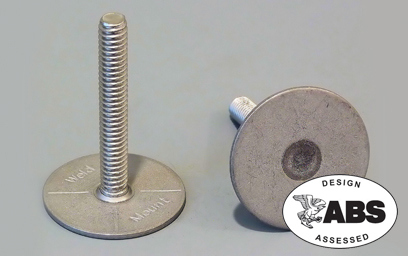

The Weld Mount SS Stud (specifically, the ST125-1420-24SS model) is a stainless steel mounting stud designed for use in marine electrical and mechanical installations. At 1.50 inches tall and featuring a 1/4″ x 20 thread pitch, this stud is bonded using Weld Mount’s unique acrylic adhesive system — offering both mechanical integrity and waterproof sealing. The 1.25-inch base ensures secure adhesion to a wide variety of marine-grade substrates including fiberglass, aluminum, and even painted surfaces.

Instead of welding or drilling, the stud is attached with a specialized acrylic adhesive that cures quickly and forms a high-strength bond. This makes the system particularly beneficial for marine applications where hull integrity, vibration resistance, and corrosion protection are critical.

Why Use Weld Mount Studs on Boats?

Choosing the right mounting hardware for your marine application is more than a convenience—it’s a matter of safety and durability. The Weld Mount SS Stud brings forward several critical advantages tailored for boating environments:

- Corrosion Resistance: Made from marine-grade stainless steel, it resists rust even in saltwater environments.

- No Drilling Required: Protects your vessel’s hull and interior components from unnecessary penetrations.

- Fast, Permanent Install: Sets in minutes using Weld Mount’s adhesive kits.

- Vibration Proof: The bond holds even under high-vibration engine environments.

These studs are commonly used for mounting wire looms, securing battery boxes, hydraulic lines, switch panels, and more. Whether you are upgrading your lighting systems or installing a new battery tray, this mounting solution ensures a clean, professional finish.

How to Install Weld Mount SS Stud

Installation of the Weld Mount SS Stud is straightforward but requires attention to detail for maximum hold and longevity. Here’s how to install the ST125-1420-24SS model properly:

- Surface Prep: Clean the mounting area thoroughly. Use isopropyl alcohol to remove oils and grime.

- Abrade Surface: Lightly sand the surface with a Scotch-Brite pad or 80-grit sandpaper to improve adhesion.

- Apply Adhesive: Use Weld Mount’s acrylic adhesive (AT-8040 or AT-6030) and apply a dab to the base of the stud.

- Position and Press: Place the stud on the surface and apply firm pressure for 15–30 seconds.

- Let It Cure: Allow 10–20 minutes for handling strength. Full cure occurs within 24 hours.

For optimal results, refer to Weld Mount’s official guides or contact your marine installer. A detailed guide for marine applications can also be found on YamahaOutboards.com.

Maintenance Tips

While the Weld Mount SS Stud is a low-maintenance component, regular checks and care ensure the mounting system continues to deliver top performance. Here are a few tips to keep your installation in peak condition:

- Check for Looseness: Occasionally inspect mounted components to ensure they haven’t shifted under vibration.

- Inspect the Adhesive Perimeter: Look for cracks, chips, or delamination at the bonding interface.

- Clean Marine Grime: Remove salt and algae deposits with fresh water and a soft brush.

- Torque Carefully: When re-fastening components, avoid overtightening which could compromise the bond.

With proper care, your installation can last for years without needing replacement or repair — even in extreme saltwater environments.

Expert Advice and Pro Recommendations

Professional marine electricians and installers agree: the Weld Mount SS Stud is a game-changer for both structural and electrical mounting. Its no-drill, no-weld installation makes it a go-to choice for retrofitting older vessels and for modern composite hulls that can be damaged by traditional fastening.

If you’re buying this product for the first time, don’t forget to bundle it with Weld Mount adhesive kits and an application gun. To get started, click here to Buy Weld Mount 1.50″ Tall 1/4 x 20 ST125-1420-24SS SS Stud 1.25″ Base 10 Pack and use code WELCOME5 to get 5% off your purchase!

Top Use Cases for Weld Mount SS Stud

The versatility of this stud allows it to be used in a wide variety of boat and marine engine environments. Here are just a few real-world applications where the Weld Mount SS Stud excels:

- Battery Box Hold-Downs: Secure heavy-duty battery boxes to non-porous surfaces without drilling.

- LED Light Mounts: Use for mounting underwater or cabin LED lighting fixtures.

- Cable Clamps: Route and secure wire bundles cleanly along bulkheads or transoms.

- Pump Brackets: Bond water or fuel pump brackets to engine compartments with vibration protection.

Whether for DIY or professional-grade installations, these mounting studs eliminate guesswork and improve safety and appearance.

Troubleshooting Common Installation Issues

Even the best marine hardware can encounter issues during or after installation. Here’s how to troubleshoot common problems with your Weld Mount SS Stud system:

Problem: Stud Comes Loose

Solution: Check surface prep. Most bond failures occur due to inadequate cleaning or abrasion. Ensure the adhesive hasn’t expired, and that the substrate is compatible.

Problem: Curing Takes Too Long

Solution: Temperature plays a big role. Adhesive cures slower below 65°F (18°C). Use a heat gun to gently warm the area for faster curing.

Problem: Cracking Around Base

Solution: This may indicate overtightening or flexing of the surface. Use a torque wrench and avoid excessive pressure during installation.

Detailed FAQ Section

What adhesive should I use with the Weld Mount SS Stud?

Weld Mount recommends using their AT-8040 or AT-6030 adhesive for bonding the ST125-1420-24SS stud. These adhesives are specifically engineered for high-strength bonding in marine environments. Both options provide a secure, waterproof seal and are easy to apply. Be sure to use the compatible applicator gun and mixing tips for best results.

Can the Weld Mount SS Stud be used on painted surfaces?

Yes, but with proper preparation. Painted surfaces must be lightly abraded to create a mechanical grip for the adhesive. Use 80-grit sandpaper or a Scotch-Brite pad and clean the area thoroughly. Some paints, especially high-gloss ones, can hinder adhesion if not properly roughed up first. Always test adhesion strength in a small area if unsure.

How much weight can the stud hold?

The Weld Mount ST125-1420-24SS can handle substantial loads. In typical installations, it can support over 300 lbs in tensile strength and around 150 lbs in shear, depending on the surface material and adhesive used. It’s important to note that full strength is achieved only after complete adhesive cure (24 hours minimum).

Can I remove the stud once installed?

Yes, but it requires heat and mechanical force. Use a heat gun to soften the adhesive (apply for 2-3 minutes), then gently twist the stud with pliers. Residual adhesive can be removed with acetone or a plastic scraper. Be cautious not to damage the surface underneath, especially if dealing with gelcoat or painted substrates.

Is this product suitable for use below the waterline?

It’s not recommended for submerged or below-waterline applications unless permanently sealed. While the stainless steel and adhesive are both water-resistant, dynamic water pressure can weaken the bond over time. For underwater installations, choose mechanical fasteners designed for wet or submerged conditions, or consult a marine professional for best practices.

Conclusion

The Weld Mount SS Stud ST125-1420-24SS model is a top-tier, corrosion-resistant mounting solution for boats and marine engines. It brings unmatched convenience, structural security, and professional-grade appearance to any boat installation — without compromising the vessel’s integrity. Whether you’re upgrading electrical systems or improving structural installations, this stud offers unparalleled versatility and strength.

Don’t wait to upgrade your marine installation process. Get your Weld Mount SS Stud today and experience the difference!

Special Offer

WELCOME5 – Get 5% off storewide at allboatsupplies.com

🚀 Instant Assistance: Need help selecting the right product? Drop your contact in the chatbox at the bottom right corner, and our expert team will reply within 30 minutes with the best product suggestion for your boat — including a ready-to-use checkout link. We’re fast, knowledgeable, and always here for your boating needs!

No more guesswork — just message us and get a personalized checkout link fast!

Let us handle the hassle — expert support, quick replies, and smooth checkout. Your boat deserves the best.

🔥 Up to 5% OFF – Limited Time!

Use code WELCOME5 on Weld Mount 1.50″ Tall 1/4 x 20 ST125-1420-24SS SS Stud 1.25″ Base 10 Pack

🚀 Buy Now – Weld Mount 1.50″ Tall 1/4 x 20 ST125-1420-24SS SS Stud 1.25″ Base 10 Pack