The Ultimate Yamaha Outboard Lower Unit Guide | Maintenance, Problems & Replacement

Every boat owner understands how vital engine care is, yet one of the most critical — and often overlooked — components is the Yamaha outboard lower unit. This assembly does the heavy lifting beneath the waterline, transferring engine power into propeller thrust to move your boat forward. Understanding how it works, how to maintain it, and when to replace it can prevent costly breakdowns and ensure years of smooth boating.

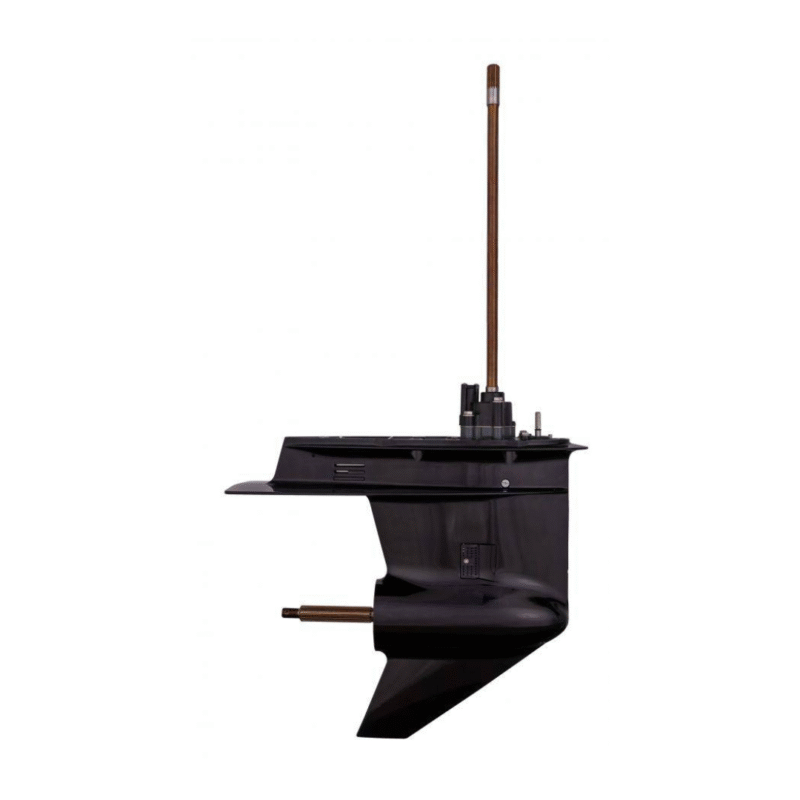

What is the Yamaha Outboard Lower Unit and Why is it Important?

Yamaha Outboard Lower Unit

The Yamaha lower unit assembly is the bottom section of your outboard motor. It houses essential components such as the gearcase, drive and propeller shafts, gears, seals, bearings, and the water pump. Essentially, it’s the power transmission system of your outboard — converting the engine’s vertical crankshaft motion into horizontal thrust through the propeller.

When functioning correctly, it ensures smooth propulsion and efficient cooling for the entire engine. If the lower unit fails, your engine may overheat, your propeller could lose drive, or your entire outboard may suffer irreversible internal damage.

Key Components of a Yamaha Outboard Lower Unit

Although compact, the lower unit contains a complex system of precision-engineered parts that work together underwater under high stress. Here’s a breakdown of its main components:

- Gearcase Housing: The external shell that protects all internal gears and shafts, typically made from high-strength aluminum alloy for corrosion resistance.

- Forward, Reverse, and Pinion Gears: These hardened steel gears transmit power from the driveshaft to the propeller shaft, allowing forward and reverse movement.

- Propeller Shaft: Connects to the propeller and rotates to push your boat through water.

- Water Pump Assembly: Includes the impeller that circulates cooling water throughout the engine. A faulty pump can cause overheating.

- Shift Rod and Clutch Dog: Engage gears when you shift between forward, neutral, and reverse.

- Seals and O-Rings: Prevent water intrusion and gear oil leakage — vital for preventing corrosion inside the unit.

- Sacrificial Anodes: Protect the metal parts from electrolysis and corrosion, especially in saltwater environments.

How the Yamaha Lower Unit Works

Here’s what happens mechanically inside your Yamaha lower unit:

- The engine’s vertical driveshaft spins from the powerhead above.

- This motion is transferred to the pinion gear at the bottom of the driveshaft.

- The pinion gear meshes with the forward and reverse gears on the propeller shaft, depending on which gear you select.

- As the propeller shaft rotates, it spins the propeller blades, propelling your boat through the water.

- Simultaneously, the water pump (located at the top of the lower unit) draws in water through intake ports and circulates it for engine cooling.

Yamaha Lower Unit Maintenance for Maximum Longevity

Keeping your Yamaha outboard lower unit in peak condition is key to ensuring long-term reliability, smooth performance, and reduced repair costs. The lower unit operates under constant load and water exposure — meaning small neglects can quickly lead to expensive failures. Below are six critical maintenance tasks every Yamaha outboard owner should perform to extend the life of their lower unit.

1. Change Gear Oil Regularly

Your lower unit’s gear oil (or lower unit lubricant) protects the internal gears, bearings, and shafts from friction and corrosion. Over time, this oil breaks down and can become contaminated with metal particles or water.

What to Do:

Change your gear oil every 100 engine hours or at least once per season (whichever comes first).

Use only Yamaha Marine Gear Lube or equivalent — automotive oil is not suitable for marine gearcases.

When draining the old oil, check for a milky or cloudy appearance — this indicates water intrusion through damaged seals.

Look for metal flakes or shavings on the magnetic drain plug, a sign of gear wear.

Always refill from the bottom drain plug upward until it seeps out the top vent hole — this ensures no air pockets remain.

Why It Matters:

Old or contaminated oil loses viscosity, causing metal-to-metal contact inside the gearcase. This accelerates gear wear, leading to grinding noises, loss of power, and potential total gear failure.

2. Inspect and Replace Seals and Gaskets

Seals and gaskets keep water out and oil in — a small failure here can ruin an entire gearcase.

What to Inspect:

Propeller Shaft Seal: Check for fishing line wrapped behind the prop, which can cut into the seal.

Driveshaft Seal & Shift Rod Seal: Inspect for cracks or hardened rubber.

Replace seals every 2–3 years or sooner if you notice leaks.

Pro Tip: When replacing seals, lightly coat them with marine grease and inspect the shafts for pitting or corrosion before reinstallation.

Why It Matters:

Even a tiny leak allows water into the gear oil, leading to rust, bearing failure, and internal corrosion that may require a full rebuild.

3. Maintain Sacrificial Anodes

Sacrificial anodes (also called zincs) protect your lower unit’s metal parts from galvanic corrosion — the electrochemical reaction that occurs when dissimilar metals are immersed in water.

Maintenance Steps:

Check anodes monthly if operating in saltwater or brackish water.

Replace when they are 50% corroded or appear chalky and pitted.

Always use Yamaha-approved anodes — never paint over them, as this prevents electrical contact.

Why It Matters:

Without functional anodes, the lower unit casing, gear housing, and prop shaft can corrode quickly, weakening the metal and leading to costly replacements.

4. Lubricate Moving Parts

Proper lubrication keeps your propeller shaft, splines, and other contact points moving smoothly and prevents rust or seizure.

What to Do:

Remove the propeller every few months and clean the shaft.

Apply marine-grade waterproof grease (Yamaha Marine Grease or equivalent) to:

Propeller shaft splines

Thrust washer

Propeller nut threads

Reinstall the prop securely and use a new cotter pin or locking tab.

Why It Matters:

A dry or corroded shaft can seize the propeller in place, making removal nearly impossible and risking shaft damage. Regular lubrication also prevents vibration and wear on the spline teeth.

5. Flush After Every Use in Saltwater

Saltwater is highly corrosive, especially to aluminum gearcases. Flushing removes salt crystals, sand, and sediment that can accumulate in the cooling passages.

How to Flush Properly:

Connect a flush hose or earmuffs to the water inlets.

Start the engine and let it idle for 5–10 minutes using fresh water.

Ensure water flows steadily from the tell-tale (indicator stream).

For engines with a flush port, you can flush without running the motor — simply attach a hose and let clean water circulate.

Why It Matters:

Unflushed salt deposits can clog cooling passages, overheat the impeller, and promote internal corrosion in both the water pump housing and the gearcase.

6. Winterization (Off-Season Storage)

If you store your boat during colder months, proper winterization prevents moisture damage, freezing, and internal corrosion.

Winterization Steps:

Drain and refill the gear oil — never store with used oil.

Run the engine to flush any salt and drain all water from the cooling system.

Remove the propeller and inspect for fishing line or damage.

Apply corrosion inhibitor spray to the lower unit’s exterior and moving parts.

Store the engine in an upright position to prevent water from collecting in the housing.

Why It Matters:

Trapped water can freeze and crack the gearcase or seals. Proper winterization ensures your outboard starts up smoothly next season without unexpected repairs.

Common Yamaha Lower Unit Problems and Warning Signs

Watch out for these signs that your lower unit may be in trouble:

- Grinding or Knocking Noise: Damaged gears or worn clutch dog components.

- Milky or Foamy Gear Oil: Indicates water contamination from leaking seals.

- Difficulty Shifting Gears: May point to a bent shift rod or internal wear.

- Propeller Vibration: Bent prop shaft or debris tangled around it.

- Loss of Power or Forward Motion: Stripped gears or broken propeller hub.

Addressing these symptoms early can prevent complete failure and a costly rebuild.

Step-by-Step: How to Replace a Yamaha Outboard Lower Unit

If your lower unit is damaged beyond repair, replacement is straightforward with the right tools and patience. Here’s how:

- Disconnect the battery and shift the motor into neutral.

- Remove the propeller and cotter pin.

- Disconnect the shift linkage and water tube connections.

- Drain the gear oil completely.

- Remove mounting bolts connecting the lower unit to the midsection.

- Carefully pull the lower unit straight down.

- Inspect and replace any worn seals or gaskets.

- Install the new or rebuilt lower unit and reconnect all linkages and fittings.

- Refill with Yamaha Marine Gear Lube.

Always use a torque wrench and refer to Yamaha’s official service manual for model-specific torque values and alignment details.

Buy Genuine Yamaha Lower Unit Online →

Why Choosing OEM Yamaha Lower Units and Parts Matters

While aftermarket parts may seem cheaper, genuine Yamaha OEM lower units are engineered with precision materials and tested for marine conditions. Here’s why OEM is worth it:

- Perfect Fit & Compatibility: OEM units match your model’s specifications exactly.

- Superior Corrosion Resistance: Yamaha uses marine-grade aluminum alloys with epoxy coatings.

- Enhanced Performance: Balanced gear sets and tolerances ensure smoother operation.

- Maintains Warranty: Using genuine parts protects your Yamaha warranty.

- Longer Lifespan: OEM units often last years longer under regular maintenance.

Troubleshooting Yamaha Lower Unit Problems

If you suspect lower unit issues, start with basic checks before disassembly:

- Check the gear oil color and level — replace if contaminated or low.

- Inspect the propeller shaft for fishing line, weeds, or rope.

- Spin the propeller by hand — it should turn smoothly without grinding.

- Listen during shifting — clunking or delay suggests clutch or gear problems.

- Test the water pump — if the telltale stream is weak, the impeller may need replacement.

If issues persist, it’s best to contact a certified Yamaha marine technician for diagnostic testing and pressure checks.

How to Extend the Life of Your Yamaha Outboard Lower Unit

To maximize the lifespan of your Yamaha lower unit:

- Change gear oil every 100 hours or twice a year.

- Flush your outboard after every use in salt or dirty water.

- Replace worn seals, anodes, and impellers promptly.

- Use only Yamaha-approved gear lube and lubricants.

- Store your boat upright and dry during off-season.

Shop Yamaha Gear Lube & Maintenance Kits →

FAQs about Yamaha Outboard Lower Unit

What is the function of the Yamaha outboard lower unit?

The lower unit transfers the engine’s power to the propeller shaft, enabling the boat to move forward or backward.How often should I change the gear oil in my Yamaha lower unit?

It is recommended to replace the gear oil every 100 hours or at least once per boating season to prevent damage and contamination.What are the warning signs of a failing Yamaha lower unit?

Signs include grinding noises when shifting, difficulty shifting gears, water in gear oil (milky appearance), and loss of propulsion power.Can I replace the Yamaha lower unit myself?

Yes, if you have basic mechanical skills and tools, but it is important to follow proper steps and use genuine Yamaha replacement parts.Why is it important to use OEM Yamaha lower units?

OEM units ensure correct fit, durability, corrosion resistance, and maintain the validity of your outboard motor warranty.

Conclusion: Keep Your Yamaha Outboard Lower Unit in Top Shape

The Yamaha outboard lower unit may operate silently beneath the surface, but it’s the powerhouse that keeps your boat moving. Understanding its operation, maintaining it regularly, and using genuine Yamaha parts can save you from downtime, costly repairs, and lost boating days.

Inspect your lower unit routinely, listen to the sounds of your motor, and don’t ignore small leaks or vibrations — they often point to bigger issues. With proactive care, your Yamaha outboard will deliver years of reliable, powerful performance on the water.

🚤 Not sure which Yamaha lower unit fits your outboard?

Contact our marine experts for personalized compatibility support — we’ll help you find the perfect match for your boat or answer any questions you have about our products.

👉 Get expert help now : Check our remanufactured Yamaha lower units now at AllBoatSupplies.com