Comprehensive Guide to Outboard Lower Units

1. What is the Yamaha Outboard Lower Unit Oil Type?

The Yamaha outboard lower unit requires SAE 90 marine-grade gear oil, such as Yamaha’s Yamalube. This type of oil is specifically designed for marine environments to protect against water contamination, rust, and gear wear. Using the wrong oil type can lead to inefficient performance or even damage to the gears and bearings.

Grab great deals on Yamaha Lower unit .

When changing the oil, always inspect it for any signs of contamination, such as a milky appearance, which may indicate water intrusion. Regularly replacing the oil ensures your Yamaha lower unit continues to operate at its best, whether you’re in saltwater or freshwater environments.

2. What is a Yamaha Outboard Lower Unit and Why Is It Important?

The Yamaha outboard lower unit is a critical part of the motor that transfers power from the engine to the propeller. It houses essential components like gears, the drive shaft, and seals. Without a well-functioning lower unit, the motor cannot propel the boat effectively.

Proper maintenance of this component includes regular oil changes, seal inspections, and flushing it after saltwater use. Neglecting this vital part can lead to costly repairs and reduce the motor’s lifespan.

3. What Is Mercury Outboard Lower Unit Assembly?

The Mercury outboard lower unit assembly refers to the installation of the lower unit components, including the gears, water pump, and drive shaft. Proper alignment and sealing are essential during assembly to prevent water from entering the lower unit.

Always follow Mercury’s specific assembly guidelines and use marine grease to protect moving parts. Regularly inspect the lower unit after assembly to ensure it operates smoothly and remains leak-free. Timely maintenance helps extend the life of your Mercury outboard motor.

4. How to Maintain a Yamaha Outboard Lower Unit Assembly?

Maintaining the Yamaha outboard lower unit assembly is essential for its longevity. Start by inspecting the seals, bolts, and gear components regularly. Replace damaged or worn parts immediately to avoid internal failures.

Ensure the assembly is properly lubricated using Yamaha’s recommended gear oil. Also, check the alignment of the gears and drive shaft. Proper maintenance ensures optimal performance and helps avoid water intrusion and corrosion.

5. Why Choose Amsoil Outboard Lower Unit Oil?

Amsoil outboard lower unit oil is a premium lubricant designed for high-performance outboard motors. It provides superior protection against wear, water intrusion, and corrosion. This oil is ideal for boaters who frequently operate in harsh environments, such as saltwater or extreme temperatures.

Using Amsoil ensures that your lower unit remains well-lubricated and free from contaminants. Its high-quality formulation offers long-lasting performance, reducing the need for frequent oil changes. Boaters who prioritize performance and durability will benefit from switching to Amsoil.

6. What is a Yamaha Outboard Lower Unit Oil Adapter?

A Yamaha outboard lower unit oil adapter simplifies the process of changing the lower unit oil. This tool ensures a secure connection to the lower unit’s drain hole, preventing spills and making the oil change efficient.

Using an adapter saves time and ensures that the proper amount of oil is filled without creating air pockets. Regular use of this tool during oil changes can streamline maintenance and protect your Yamaha outboard motor.

7. How Does an Outboard Lower Unit Work?

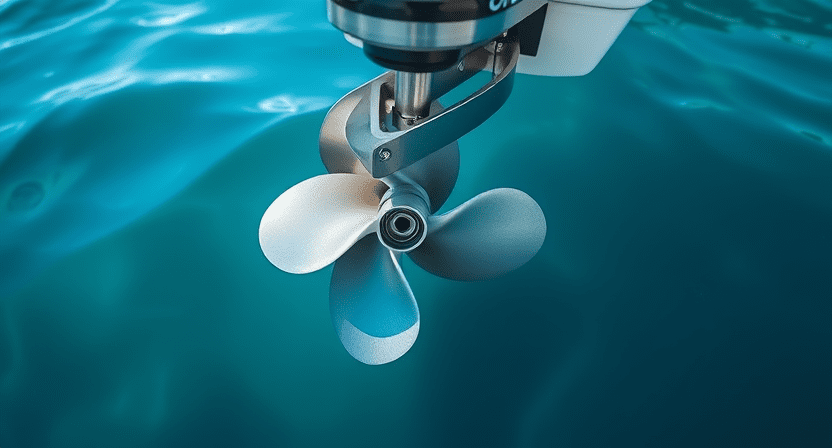

The outboard lower unit transfers the engine’s power to the propeller, enabling the boat to move forward or backward. It consists of gears, a drive shaft, and a water pump. The gears adjust the propeller’s speed and direction, while the water pump cools the engine by circulating water.

A well-maintained lower unit ensures efficient power transfer and prevents overheating. Regular inspections and oil changes are vital for keeping the unit functioning properly.

8. What is the Lower Unit of an Outboard Motor?

The lower unit of an outboard motor is a gearbox located at the bottom of the motor. It contains essential components like the gears, propeller shaft, and seals. This part plays a vital role in propelling the boat and cooling the engine.

Routine maintenance, such as oil changes and seal inspections, prevents failures and extends the lower unit’s lifespan. Understanding how this component works helps you identify potential problems early.

9. What Are the Parts of an Outboard Lower Unit?

The parts of an outboard lower unit include the drive shaft, gears, propeller shaft, seals, and water pump. Each part works together to transfer power from the engine to the propeller and cool the engine.

Inspect these parts regularly to ensure they are free from wear or damage. Replacing worn components promptly can prevent expensive repairs and keep your outboard motor operating smoothly.

10. What Causes an Outboard Lower Unit to Fail?

Several factors can cause an outboard lower unit to fail. Common reasons include water intrusion, insufficient lubrication, worn seals, and physical damage to the gears or casing. Running the motor with old or contaminated oil can also lead to overheating and gear wear.

Regular maintenance, such as timely oil changes and inspections, reduces the risk of failure. Additionally, flushing the motor after saltwater use helps prevent corrosion, a common cause of lower unit damage. Early detection and repair of issues can save you from costly replacements.

In this Comprehensive Guide to Outboard Lower Units you can built a great knowledge .