Weld Mount SS Stud – Pros & Cons Explained

Introduction

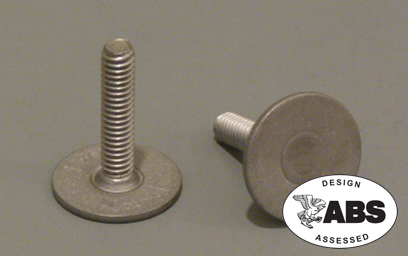

The weld mount ss stud is one of the most innovative and reliable fastening solutions available for marine environments. Designed to function where traditional fasteners fail, the Weld Mount 1.00″ Tall #8 x 32 PS62-832-16SS SS Stud 0.62″ Base 15 Pack provides a powerful hold without the need for drilling or tapping, which is ideal for maintaining the integrity of boat hulls, panels, and engine compartments. Made from high-quality stainless steel and engineered for bonding with adhesives like AT-8040 or AT-2010, this product is a game-changer in the boating world.

Whether you’re performing electrical installations, securing panels, or customizing your boat’s interior, this weld mount stud provides unmatched strength, corrosion resistance, and convenience. It’s ideal for boaters who want a cleaner, faster, and more durable installation method.

Overview / What Is Weld Mount SS Stud

The weld mount ss stud is a stainless steel threaded stud designed to be bonded to surfaces using structural adhesives rather than requiring traditional welding or drilling. This specific product — with a height of 1.00″, a #8 x 32 thread, and a 0.62″ base — is perfect for high-vibration areas in marine and engine applications.

Constructed from 316 stainless steel, this weld mount fastener offers superior resistance to corrosion, especially in saltwater environments. The PS62-832-16SS model is ideal for light to medium-duty applications, including mounting electronics, conduits, cable trays, and hose clamps.

Why Use Weld Mount Studs for Boats?

Boat owners and marine technicians choose weld mount ss studs for a variety of practical reasons. Traditional screws and bolts can compromise the waterproof integrity of your vessel when installed improperly. Here’s why the Weld Mount solution stands out:

- No Drilling Required: Protects gel coat and avoids water ingress.

- Permanent Bonding: Bonds with Weld Mount adhesives like AT-8040 or AT-2010.

- Vibration Resistant: Maintains secure fastening under rough marine conditions.

- Easy Installation: Mounts in under 2 minutes with proper adhesive and curing.

These features make this product the best option for retrofitting, rigging, and custom installations on boats and marine engines.

Maintenance Tips

While the weld mount ss stud is designed for durability and corrosion resistance, proper care extends its lifespan even further. Here are a few essential tips:

- Clean Surface Before Bonding: Always degrease and dry the bonding surface to ensure maximum adhesion.

- Use Compatible Adhesives: Use with Weld Mount’s approved adhesives like AT-8040 or AT-2010 for marine environments.

- Inspect Annually: Especially in high-stress areas, check for signs of corrosion or delamination annually.

- Avoid Over-Tightening: Torque wrenches help prevent mechanical strain during mounting.

These practices ensure the reliability and long-term performance of the welded mount solution on any watercraft.

Best Weld Mount SS Stud Use Cases on Marine Engines

The weld mount ss stud is extremely versatile across a variety of marine engine and boat applications. Here are common use cases:

- Securing Hose Clamps: On fuel, coolant, or hydraulic lines.

- Mounting Electrical Panels: For breaker boxes and terminal strips.

- Fastening Cable Trays: Ideal for wire management in engine bays.

- Mounting Relays and Fuses: Safe, secure bonding in confined engine spaces.

Because it avoids the need for drilling into fiberglass or composite panels, this product helps maintain the structural and aesthetic integrity of your vessel.

How to Install Weld Mount SS Stud

Installing the weld mount ss stud is a simple process if you follow the right steps:

- Surface Prep: Clean with isopropyl alcohol and abrade lightly with sandpaper.

- Apply Adhesive: Use a mixing tip with AT-8040 or AT-2010 for a consistent bond line.

- Press & Hold: Hold the stud firmly in place for 10–15 seconds until tack-free.

- Cure Time: Allow 5–6 hours for full strength (depending on adhesive).

After curing, your stud is ready for mechanical fastening and will deliver reliable performance under high load or vibration.

Expert Advice and Pro Recommendations

Marine professionals agree that the weld mount ss stud is a time-saver and a safer alternative to mechanical drilling. It’s particularly useful for custom builds or complex retrofits where access is limited and traditional mounting is not feasible.

Buy now: Weld Mount 1.00″ Tall #8 x 32 PS62-832-16SS SS Stud 0.62″ Base 15 Pack and enjoy 5% off using code WELCOME5. Trusted by OEM boat builders, these studs work reliably on aluminum, fiberglass, and even carbon fiber substrates.

Detailed FAQ Section

What adhesive should I use with Weld Mount SS Studs?

The best adhesives for bonding the weld mount ss stud are AT-8040 (fast curing) and AT-2010 (general purpose). These are designed specifically for the marine environment and cure quickly under moderate conditions. They resist heat, vibration, saltwater, and provide a permanent bond that outlasts typical epoxy alternatives.

How much weight can a Weld Mount SS Stud hold?

When used with Weld Mount’s recommended adhesives and properly cured, each weld mount ss stud can support up to 200 lbs of pull strength and 500 lbs of shear strength under optimal conditions. Load-bearing capacity depends on surface prep, orientation, and environmental conditions. For critical applications, always verify specs with load testing.

Can I install these studs vertically or overhead?

Yes, the weld mount ss stud can be installed in any orientation — including overhead — when using a thixotropic adhesive like AT-8040 that prevents sagging. For overhead applications, ensure proper curing and clean surfaces before installation. Holding in place for initial set time is crucial.

How long does the adhesive take to cure completely?

Weld Mount adhesives cure to 80% strength within the first hour, but full strength is achieved in 5–6 hours. Cold or humid environments may extend curing times slightly. Heat may reduce it. It’s advised to avoid load application until the full cure time is complete for safety and long-term reliability.

Is this stud compatible with all marine substrates?

The weld mount ss stud works on most boat-building materials, including aluminum, stainless steel, fiberglass, composites, and painted surfaces. Always test a small area first for compatibility. Using this system eliminates risk of delamination or moisture ingress common with drilled fasteners. Learn more at Yamaha Outboards for additional insights into compatible mounting methods.

Conclusion

The weld mount ss stud offers a modern solution to fastening problems faced by boat owners and marine technicians. Its no-drill, no-weld design simplifies installations while preserving the strength and structure of your vessel. Whether you’re managing wires, mounting panels, or customizing components, this product delivers lasting reliability and professional results.

Special Offer

WELCOME5 – Get 5% off storewide at allboatsupplies.com

🚀 Instant Assistance: Need help selecting the right product? Drop your contact in the chatbox at the bottom right corner, and our expert team will reply within 30 minutes with the best product suggestion for your boat — including a ready-to-use checkout link. We’re fast, knowledgeable, and always here for your boating needs!

No more guesswork — just message us and get a personalized checkout link fast!

Let us handle the hassle — expert support, quick replies, and smooth checkout. Your boat deserves the best.

🔥 Up to 5% OFF – Limited Time!

Use code WELCOME5 on Weld Mount 1.00″ Tall #8 x 32 PS62-832-16SS SS Stud 0.62″ Base 15 Pack

🚀 Buy Now – Weld Mount 1.00″ Tall #8 x 32 PS62-832-16SS SS Stud 0.62″ Base 15 Pack

Read More

For more helpful marine maintenance guides, check out our article on Weld Mount AT-5 Mount Large Black 30 Pack – Best & Worst Use Cases.