Weld Mount SS Stud – Durable or Disappointing?

Weld Mount 1.25″ Tall #10 x 24 ST125-1024-20SS SS Stud 1.25″ Base 10 Pack for Boats & Marine Engines

Introduction

When working with electrical and lighting installation accessories on boats and marine engines, choosing the right fastener can make or break your build. The Weld Mount SS Stud, specifically the Weld Mount 1.25″ Tall #10 x 24 ST125-1024-20SS SS Stud with 1.25″ Base in a 10-pack, offers a professional-grade solution for securing components without drilling. Built for durability, vibration resistance, and simplicity, this product is a game-changer for marine applications.

Used in engine compartments, hull interiors, and complex electrical setups, this product fits squarely within the Electrical & Lighting > Installation Accessories category for good reason. But is the Weld Mount SS Stud your next must-have or a risk on your vessel? Let’s take a closer look.

Overview / What Is Weld Mount SS Stud

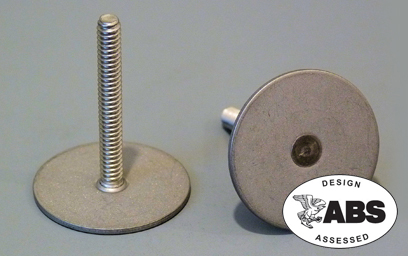

The Weld Mount SS Stud is a stainless steel bonding stud designed to be mounted using a compatible acrylic adhesive system, eliminating the need for mechanical fasteners or through-hull drilling. Its threaded configuration (#10-24) and 1.25″ base provide stability and wide applicability across various marine platforms. Sold in packs of ten, it allows installers to create multiple anchor points for electrical panels, conduit clamps, control boxes, and more.

Key Features:

- Material: Marine-grade stainless steel for corrosion resistance

- Thread Size: #10 x 24

- Stud Height: 1.25 inches

- Base Diameter: 1.25 inches for enhanced bonding area

- Quantity: 10 studs per pack

As part of a no-drill installation solution, the Weld Mount SS Stud ensures both structural integrity and aesthetic cleanliness.

Applications of Weld Mount SS Stud in Marine Settings

The versatility of the Weld Mount SS Stud makes it a perfect choice for both DIY and professional marine technicians. Whether you’re installing a new system or retrofitting an older vessel, here’s how these studs come in handy:

- Engine Compartment Wiring: Secure wire looms and harnesses without metal screws that could rust or loosen.

- Deck Panel Mounting: Mount panels beneath decks or in lockers without back-access.

- Accessory Mounting: Install plumbing clips, battery trays, or fuse blocks with vibration resistance.

- Cabin Installations: Ideal for cabinetry or bulkhead applications where appearance and stability matter.

This stud system supports a wide range of marine installation accessories without compromising the hull or core integrity.

How to Install Weld Mount SS Stud Correctly

For anyone wondering how to install Weld Mount SS Studs for long-term reliability, the process is straightforward yet crucial:

- Surface Prep: Clean with alcohol and scuff with fine-grit sandpaper to promote adhesion.

- Apply Adhesive: Use the recommended Weld Mount acrylic adhesive for secure bonding.

- Press & Hold: Place the base against the surface and hold until adhesive begins to set (approx. 2–4 minutes).

- Let Cure: Allow 24 hours for full curing before applying stress or load.

Tip: Use temporary tape or weights to secure alignment during curing for vertically or overhead-mounted studs.

Cost and Durability of Weld Mount SS Stud

When evaluating marine installation accessories, cost and durability are primary factors. At first glance, the Weld Mount SS Stud may appear pricier than traditional fasteners. However, consider these points:

- No Drilling: Saves labor costs and eliminates risk of hull damage.

- Stainless Steel Build: Outlasts most zinc or aluminum alternatives, especially in saltwater environments.

- Bulk Pack Efficiency: The 10-pack format ensures value for fleet upgrades or multi-point mounting projects.

The payoff? Long-term durability with reduced maintenance and failure risks.

Maintenance Tips

Though designed for long-term durability, following maintenance practices will ensure your Weld Mount SS Stud system stays in peak condition:

- Inspect Every 6–12 Months: Check for corrosion, adhesive breakdown, or mechanical stress.

- Reapply Adhesive When Needed: If you notice movement or failure, remove and clean surfaces thoroughly before re-bonding.

- Keep it Dry During Cure: Moisture can compromise bonding strength, so plan installs in controlled environments when possible.

Maintenance is minimal but essential for mission-critical electrical and structural marine applications.

Expert Advice and Pro Recommendations

Marine experts consistently favor the Weld Mount SS Stud for its vibration resistance, strength, and adaptability. Many pros use it in tight compartments where drilling is not just inconvenient—it’s impossible. When combined with the Weld Mount AT-8040 adhesive, the studs become nearly permanent yet leave no exposed screw heads or bolt tails.

For best results, always:

- Use a level to ensure alignment before adhesive sets.

- Pair with stainless steel washers and locking nuts for high-vibration zones.

- Avoid over-tightening, which can shear the bond or twist the stud.

Buy now: Weld Mount 1.25″ Tall #10 x 24 ST125-1024-20SS SS Stud 1.25″ Base 10 Pack and use code WELCOME5 to save 5% instantly.

Detailed FAQ Section

Can Weld Mount SS Studs support heavy electrical components?

Yes, the Weld Mount SS Studs can support moderate to heavy electrical components as long as proper installation procedures are followed. Each stud is bonded using high-strength acrylic adhesive capable of handling dynamic loads. It is ideal for mounting fuse panels, electrical junction boxes, and relays in engine bays or under-deck compartments. However, it’s critical to understand the weight rating of the adhesive bond and avoid overloading a single stud. If the component is particularly heavy or prone to vibration, using multiple studs spaced evenly is recommended to distribute the load.

What is the best adhesive to use with Weld Mount SS Stud?

For optimal results, the Weld Mount AT-8040 acrylic adhesive is the manufacturer-recommended bonding agent. It’s formulated specifically for use with stainless steel studs on fiberglass, aluminum, and coated metal surfaces. This adhesive offers fast setting times (typically within 4–6 minutes) and full cure in 24 hours. It is resistant to fuel, oil, and saltwater, making it perfect for marine environments. Users should ensure surfaces are clean and properly prepped before applying. Do not use general-purpose epoxy or silicone sealants, as they lack the structural bonding properties needed for this application.

Can these studs be used for mounting accessories on the exterior hull?

While technically possible, using Weld Mount SS Studs on the exterior hull is not advised unless they are completely protected from direct water flow and UV exposure. These studs are best suited for internal mounting where they are shielded from harsh elements. The acrylic adhesive may degrade faster under UV light or in areas exposed to constant water spray or hull impact. For topside or exterior installations, consider through-bolting with marine-grade sealants or use studs designed specifically for topside weather exposure.

How do I remove a Weld Mount SS Stud without damaging the surface?

Removing a bonded stud can be tricky and may lead to surface damage if not done carefully. Begin by applying localized heat using a heat gun to soften the adhesive. Use a pair of pliers to gently twist the stud back and forth while applying heat. Once removed, use a plastic scraper to lift any remaining adhesive. Avoid using metal scrapers that can gouge fiberglass or aluminum. Clean the area with adhesive remover or acetone and refinish the surface if necessary. Removal is not always guaranteed to be damage-free, so plan installation positions carefully.

Are there any alternative uses for Weld Mount SS Studs?

Yes. In addition to marine use, Weld Mount SS Studs are often used in RVs, industrial vehicles, aircraft, and commercial kitchens—anywhere drilling through the mounting surface is discouraged. They are perfect for hanging tool brackets, securing lightweight storage bins, organizing wire harnesses, or mounting decorative panels. Their flexibility and strength make them one of the most reliable non-drill fastener solutions in the market. Check out other compatible uses and solutions at Yamaha Outboards.

Conclusion

Whether you’re overhauling your boat’s electrical system or outfitting a new engine bay, the Weld Mount SS Stud is a reliable solution for mounting without drilling. Built from marine-grade stainless steel and designed for strong adhesive bonds, these studs offer convenience, strength, and long-term durability. From professionals to weekend warriors, this 10-pack kit is a smart investment for safe, non-invasive mounting.

Special Offer

WELCOME5 – Get 5% off storewide at allboatsupplies.com

🚀 Instant Assistance: Need help selecting the right product? Drop your contact in the chatbox at the bottom right corner, and our expert team will reply within 30 minutes with the best product suggestion for your boat — including a ready-to-use checkout link. We’re fast, knowledgeable, and always here for your boating needs!

No more guesswork — just message us and get a personalized checkout link fast!

Let us handle the hassle — expert support, quick replies, and smooth checkout. Your boat deserves the best.

🔥 Up to 5% OFF – Limited Time!

Use code WELCOME5 on Weld Mount 1.25″ Tall #10 x 24 ST125-1024-20SS SS Stud 1.25″ Base 10 Pack

🚀 Buy Now – Weld Mount 1.25″ Tall #10 x 24 ST125-1024-20SS SS Stud 1.25″ Base 10 Pack