Evinrude 763457 Propeller Maintenance for Corrosion

When it comes to maintaining your Evinrude 763457 propeller, proper care and regular maintenance are essential to ensure its longevity and performance. One of the most significant challenges boaters face is corrosion, especially in marine environments where saltwater and other elements can wreak havoc on propellers. In this blog, we will explore effective maintenance techniques to combat corrosion and extend the life of your Evinrude 763457 propeller.

Grab a great deals on AllBoatSupplies.com .

Understanding Propeller Corrosion and Its Impact

Corrosion is the gradual deterioration of metals due to environmental factors. In the case of marine propellers, exposure to saltwater, humidity, and other corrosive agents accelerates the process. Outboard lower units, including the propeller, are especially vulnerable due to constant submersion in water. If left unaddressed, corrosion can lead to reduced performance, vibration issues, and even complete propeller failure.

Key Components Affected by Corrosion

Before diving into maintenance tips, it’s important to understand which components are most susceptible to corrosion:

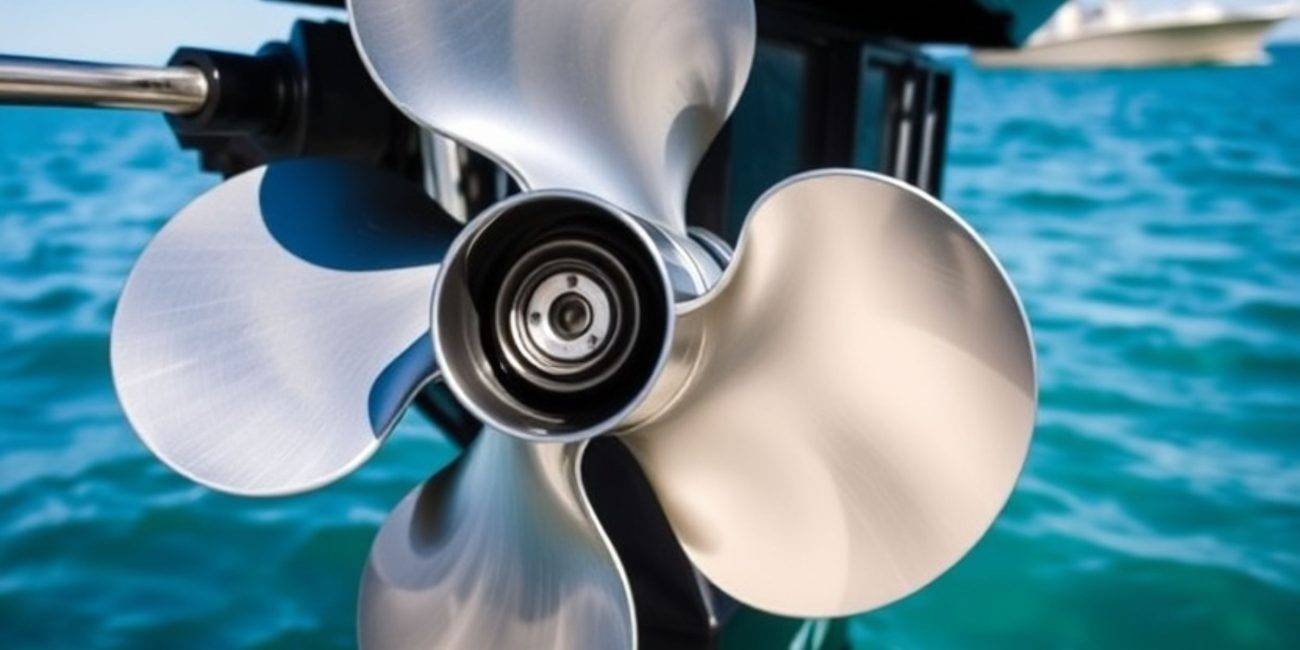

- Propeller Blades: Constant exposure to saltwater and debris can cause pitting and erosion on the blades, leading to a decrease in efficiency and performance.

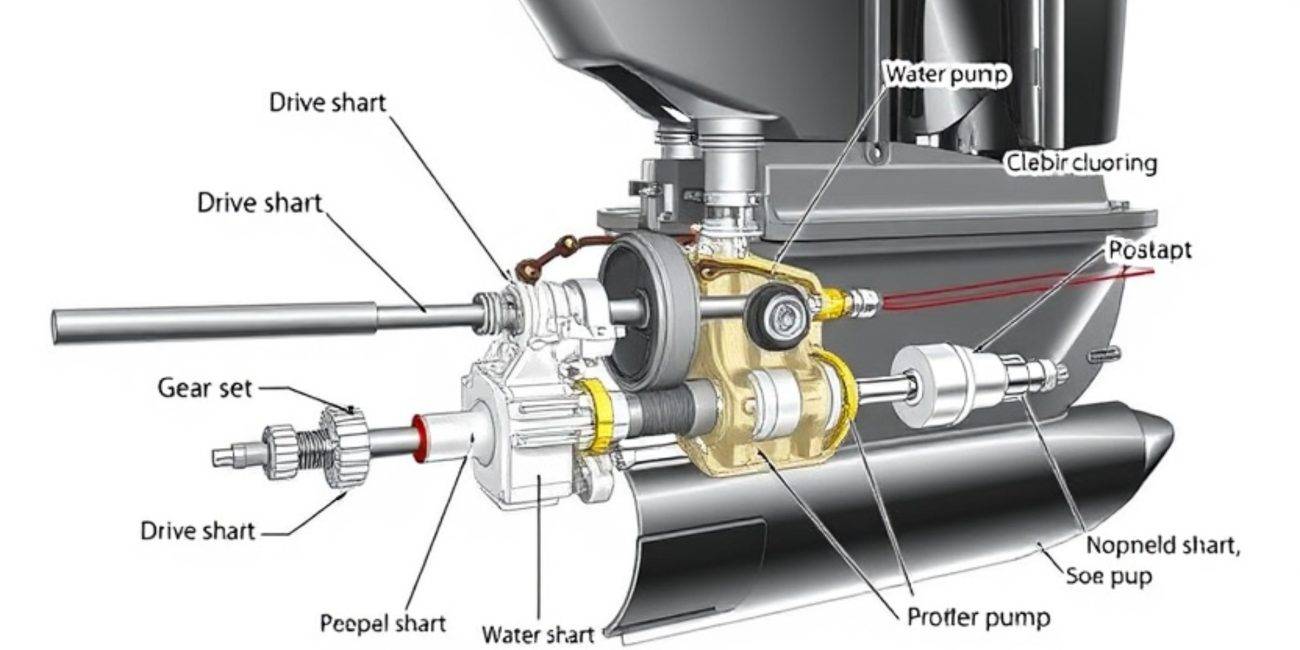

- Outboard Lower Unit: The outboard lower unit houses the gearcase and propeller shaft, both of which are prone to corrosion when exposed to harsh environmental conditions.

- Propeller Hub: This area connects the propeller to the shaft. If the hub corrodes, the propeller could become loose or even detach from the outboard motor.

- Anodes: Sacrificial anodes are designed to protect key metal components, but over time, they wear down and need to be replaced to prevent corrosion.

Routine Maintenance for the Evinrude 763457 Propeller

To protect your Evinrude 763457 propeller from corrosion and maintain its performance, follow these essential maintenance steps:

1. Regular Cleaning and Inspection

After every use, particularly in saltwater, rinse your propeller and outboard lower unit thoroughly with fresh water. Use a soft brush to remove any debris that may have accumulated on the blades or around the hub. This helps prevent salt and other corrosive elements from building up.

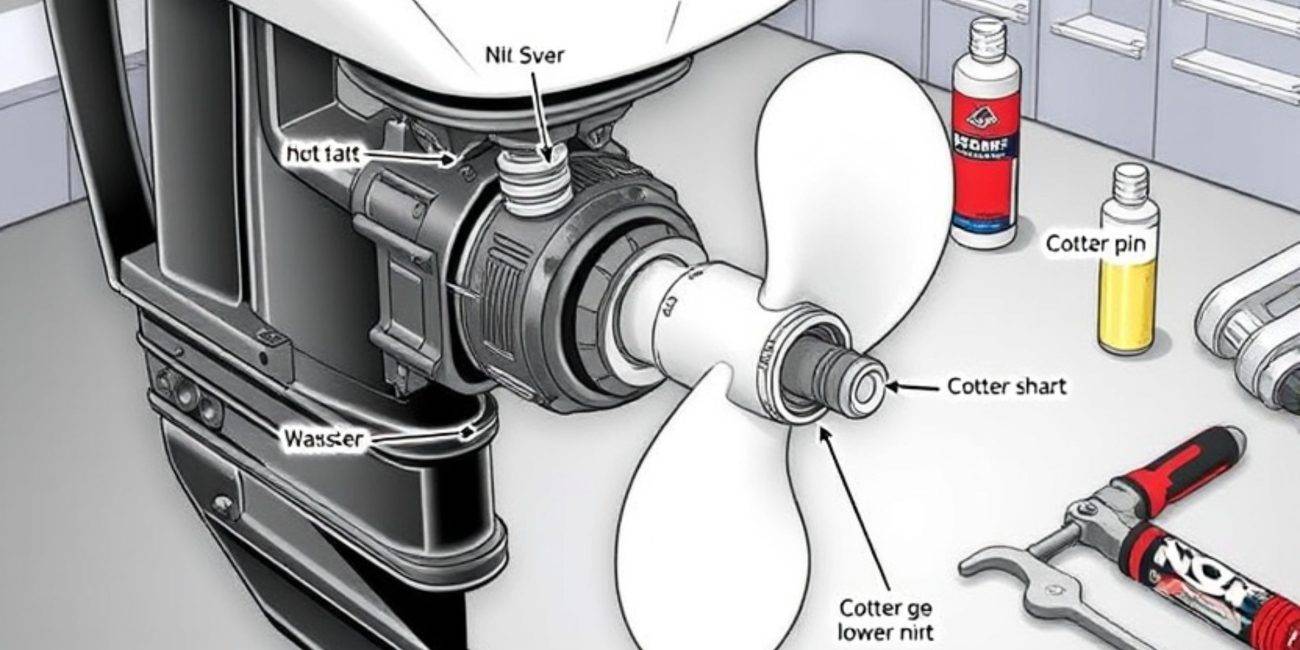

2. Lubrication of Moving Parts

Lubricating the moving parts of the propeller and the outboard lower unit will help reduce friction and minimize the chances of corrosion. Use high-quality marine grease, ensuring that you apply it to the propeller shaft and other critical areas. Be sure to check for any signs of wear or damage while lubricating.

3. Check for Corrosion and Pitting

Inspect the Evinrude 763457 propeller regularly for signs of corrosion, including pitting or discoloration. If you notice any early signs of damage, it’s best to address them immediately by cleaning and applying anti-corrosion treatments.

4. Replace Sacrificial Anodes

As mentioned earlier, sacrificial anodes play a crucial role in protecting your outboard lower unit and propeller from corrosion. These anodes degrade over time and must be replaced regularly to continue providing effective protection.

5. Proper Storage and Drying

Proper storage of your boat and propeller can significantly extend their lifespan. After each use, store your boat in a dry area, and ensure the outboard lower unit and propeller are free from water. If you store your boat in saltwater, remove the propeller and clean it thoroughly.

Corrosion-Resistant Propeller Materials

To minimize the effects of corrosion, many propeller manufacturers, including Evinrude, now offer corrosion-resistant propellers made from advanced alloys or coated with protective finishes. These materials are designed to withstand the harsh marine environment and provide longer-lasting performance. Consider upgrading to a corrosion-resistant propeller if you frequently boat in saltwater.

Signs That Your Propeller Needs Maintenance

It’s crucial to stay vigilant and monitor your Evinrude 763457 propeller for signs that it may need attention. Common signs of propeller damage include:

- Increased Vibration: If you notice unusual vibration or noise during operation, it could indicate a problem with the propeller or outboard lower unit.

- Decreased Performance: A loss of speed or poor acceleration may be due to damage to the propeller blades or corrosion on the hub.

- Visible Damage: Cracks, chips, or erosion on the propeller blades are all indicators that maintenance is required.

Conclusion

In conclusion, proper Evinrude 763457 propeller maintenance is essential for ensuring the longevity and performance of your propeller and outboard motor. Regular cleaning, lubrication, and inspections, along with replacing sacrificial anodes, can help prevent corrosion and reduce the risk of costly repairs. Additionally, upgrading to corrosion-resistant propellers can further enhance your protection against marine corrosion. With these maintenance tips, you can keep your Evinrude 763457 propeller in top condition, ensuring smooth sailing for years to come.

For more insights, check out our previous blog: “Does the SolAS Rubex 9513-145-15 propeller reduce vibration.”