5 Key Signs It’s Time to Replace Your Outboard Lower Unit

5 Key Signs It’s Time to Replace Your Outboard Lower Unit

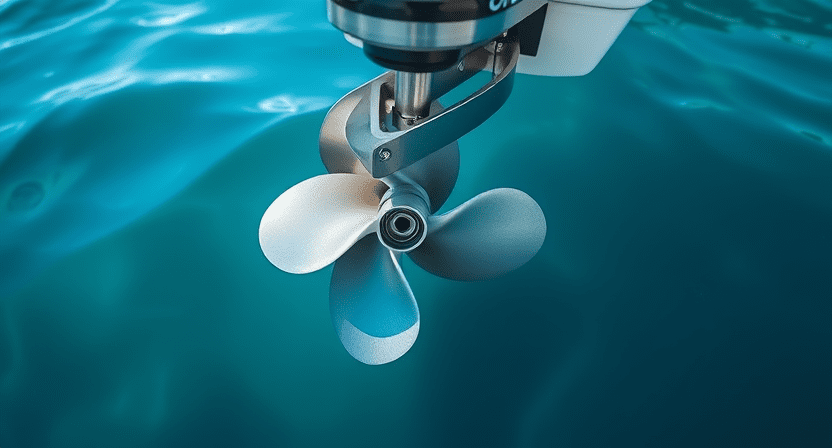

Your outboard lower unit plays a critical role in transferring power from the engine to the propeller, ensuring your boat operates efficiently and know what are the signs to replace outboard lower unit. However, continuous exposure to harsh marine conditions can cause wear and tear over time. Recognizing early signs of trouble with your outboard lower unit can prevent costly repairs and maintain your boat’s performance.

Here are five key signs it’s time to replace your outboard lower unit.

1) Unusual Grinding or Whining Noises

If your boat engine starts emitting grinding or whining noises, it’s a clear indication of trouble within the lower unit. These sounds typically result from worn-out or misaligned gears, damaged bearings, or a lack of proper lubrication. Grinding noises occur when the gear teeth are damaged, while whining sounds often point to issues with bearings or improper alignment.

Ignoring these noises can lead to catastrophic damage, so it’s vital to act immediately. Shut off the engine, inspect the lower unit, and check the condition of the gear oil. If the problem persists, replacing the lower unit may be necessary. Regular maintenance, such as changing the gear oil and inspecting seals, can help prevent such issues.

2) Leaking Oil or Water Intrusion

Leaking oil or water intrusion into the lower unit signals a seal or gasket failure. A healthy lower unit relies on a watertight seal to keep water out and oil in. If water mixes with the gear oil, it can lead to rust and corrosion, significantly damaging internal components like gears and bearings.

To check for this issue, inspect the lower unit oil. Milky or discolored oil is a strong indicator of water intrusion. Address this immediately by replacing damaged seals or gaskets. If internal corrosion has already occurred, a complete lower unit replacement might be the best course of action. Regularly inspect the lower unit for leaks to catch problems early.

3) Decreased Propeller Performance or Excessive Vibrations

A drop in propeller efficiency or noticeable vibrations during operation could mean internal wear or damage in the lower unit. The lower unit contains essential components like the driveshaft and bearings, which are directly connected to the propeller’s performance.

If you experience poor performance, check for damage to the propeller and the driveshaft. Excessive vibrations could be caused by bent or worn-out parts, which place undue stress on the lower unit. Persistent issues might require replacing the entire lower unit to restore smooth and efficient operation.

Routine checks of the propeller and lower unit components can help prevent these issues and ensure your boat operates effectively.

4) Overheating or Excessive Heat

Overheating in the engine can often be traced back to a malfunction in the cooling system housed in the lower unit. A faulty water pump, damaged impeller, or blockages in the cooling passages are common culprits. Overheating can cause significant damage to internal components, reducing the efficiency of your engine and lower unit.

To address overheating, check the impeller and water pump for damage or blockages. If these components are functioning poorly, replace them promptly. Persistent overheating issues might necessitate replacing the entire lower unit to protect your engine.

5) Strange Metal Shavings in Gear Oil

During regular maintenance, it’s crucial to inspect the lower unit oil for any signs of contamination. If you find metal shavings or debris in the oil, it indicates excessive wear and tear on the gears or bearings. This is often caused by prolonged use without adequate lubrication or due to internal damage.

Metal contamination can lead to severe mechanical failure if left unchecked. If metal shavings are present, stop using the engine and conduct a thorough inspection. If the damage is extensive, replacing the lower unit may be the only way to ensure reliable operation. Regular oil changes and using the correct type of gear oil can help prevent such issues.

Conclusion

Recognizing these five signs early can save you from costly repairs and ensure your boat remains safe and efficient. Regular maintenance of your outboard lower unit, such as inspecting oil levels, seals, and internal components, is the key to avoiding unexpected failures. If you notice any of these issues and repairs aren’t viable, investing in a new lower unit can restore your boat’s performance and reliability.

By staying proactive, you can extend the life of your boat’s engine and enjoy smooth sailing every time you hit the water.