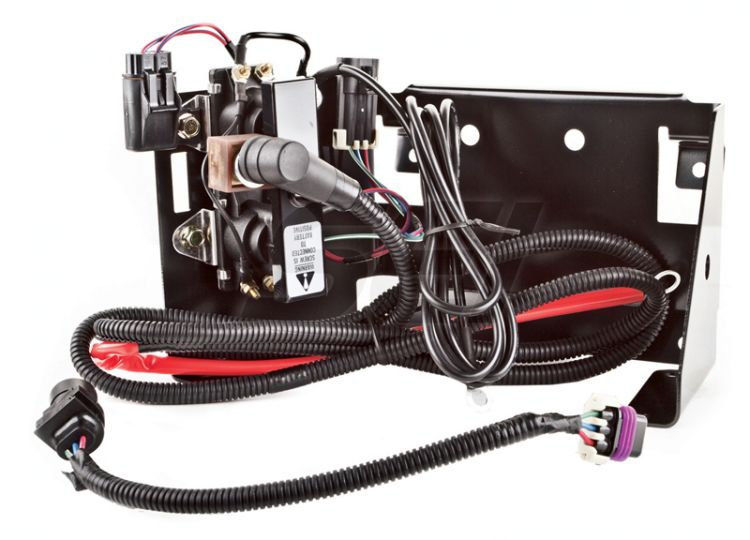

Trim Pump Mounting Bracket Assembly

Introduction

The Trim Pump Mounting Bracket Assembly for boats and marine engines is a crucial component for securing the trim pump firmly to your vessel. Whether you’re maintaining a high-performance Mercruiser Alpha One Gen I system or simply ensuring your boat operates efficiently on the water, this bracket ensures your trim pump stays perfectly mounted in place. Boaters who prioritize safety, performance, and structural integrity will appreciate the reliability this bracket offers, especially in rough marine conditions.

This article dives deep into everything you need to know about the trim pump mounting bracket assembly for marine setups — from its function and benefits to expert tips and FAQs. Whether you’re a boat owner, technician, or marine enthusiast, this guide covers it all.

Overview / What Is Trim Pump Mounting Bracket Assembly?

A trim pump mounting bracket is designed to hold the hydraulic trim pump securely in place within your boat’s engine compartment. It serves both structural and safety purposes, making sure the pump stays mounted correctly under dynamic marine conditions. This is especially important for boats using Mercruiser Alpha One Gen I sterndrives, where accurate trim operation impacts performance and maneuverability.

Typically manufactured from marine-grade stainless steel or powder-coated aluminum, these brackets resist corrosion and wear caused by saltwater exposure. The bracket is engineered for exact fitment, and includes all mounting holes for easy installation.

Key Features of the Trim Pump Mounting Bracket

- High-strength corrosion-resistant materials

- Compatible with Mercruiser Alpha One Gen I trim pumps

- Pre-drilled holes for quick installation

- Secure and vibration-free mount for hydraulic pumps

- OEM-equivalent performance and design

This simple but essential component is vital in ensuring your trim pump doesn’t vibrate loose or misalign, preventing expensive damage or malfunction.

Why a Secure Trim Pump Bracket Matters

Improper or failing trim pump mounting can result in hydraulic hose stress, pump misalignment, or complete detachment. This leads to trim failure, which in high-speed situations can affect stability, steering, and safety. A reliable trim pump bracket for marine engines eliminates such risks by maintaining the correct orientation and vibration dampening of the hydraulic system.

Using the recommended bracket assembly ensures longer service life for the trim pump, reduces mechanical stress on hoses, and delivers more responsive trim performance on the water. It’s a small investment that safeguards your engine system’s integrity.

How to Install Trim Pump Mounting Bracket for Marine Use

Installing the trim pump bracket is a simple but critical process. Here are the basic steps:

- Turn off your battery and relieve hydraulic pressure.

- Unbolt the current trim pump (if replacing the bracket).

- Position the new bracket and align the mounting holes.

- Secure the bracket with corrosion-resistant bolts.

- Reinstall the pump and connect hydraulic lines carefully.

Make sure the pump is sitting flush without tension on hoses. A slight misalignment can cause future leaks or mechanical failures. Use marine-grade bolts and anti-corrosion compound during installation.

Maintenance Tips

Regular maintenance of your trim pump bracket for marine applications ensures the longevity of both the bracket and the pump. Here are some tips to keep your system in top shape:

- Inspect for corrosion: Especially if you’re boating in saltwater. Clean and recoat or replace if necessary.

- Tighten bolts: Regularly check torque settings and ensure no bolts have vibrated loose.

- Clean the surface: Use a mild marine cleaner to prevent buildup and rust formation.

- Check alignment: Make sure the pump remains level and hoses aren’t stressed.

Preventive care minimizes the risk of malfunction and ensures your trim system operates smoothly.

Common Problems and Troubleshooting the Mounting Bracket

If your trim system is acting up, the mounting bracket might be to blame. Here’s how to troubleshoot:

- Excessive vibration: Check bracket bolts and bushings for wear or looseness.

- Unusual noises: A misaligned bracket can cause the pump to rattle or whine.

- Trim delay: If the pump is not secure, it can restrict hydraulic flow efficiency.

In most cases, realigning or replacing the bracket resolves these issues. Make sure to inspect the bracket during every engine compartment inspection.

Expert Advice and Pro Recommendations

Marine mechanics recommend replacing the trim pump mounting bracket every 5–7 years or immediately if signs of wear, rust, or vibration are evident. For best results, match the bracket exactly to your pump and engine model.

Using OEM or high-quality aftermarket parts, such as those from Trim Pump Mounting Bracket Assembly, ensures long-lasting performance. These brackets come pre-aligned and treated for marine corrosion resistance, and include a 5% off code: WELCOME5 on purchase.

Detailed FAQ Section

What is the primary purpose of a trim pump mounting bracket?

The trim pump mounting bracket is designed to securely hold the hydraulic trim pump in position inside the engine compartment. This bracket is essential for ensuring that the trim pump operates without shifting, vibrating, or disconnecting. Without it, the trim pump could experience unnecessary wear or even failure due to stress or misalignment. The bracket helps absorb vibrations and maintains optimal alignment of the hydraulic lines. In marine environments, especially with Mercruiser Alpha One Gen I engines, it’s vital for maintaining trim efficiency and preventing sudden system failure while underway.

How do I know if my trim pump bracket needs replacing?

Signs that your trim pump bracket may need replacing include visible corrosion, cracked or missing bolts, pump vibration during operation, or misalignment of the hydraulic unit. If your trim pump sounds louder than usual or if the trim response is slower, it could also indicate a mounting issue. During routine engine checks, inspect the bracket for rust or fatigue, especially in saltwater conditions. Regular inspections can prevent more costly damage to the pump or hydraulic hoses by catching a failing bracket early.

Can I install the trim pump bracket myself?

Yes, most boat owners with basic mechanical skills can install the trim pump bracket. It typically involves disconnecting the trim pump, removing the old bracket (if any), positioning the new bracket, and securing it with bolts. Once aligned, the pump is reinstalled onto the bracket and the hydraulic lines are reconnected. However, always refer to your boat’s manual or engine guide for precise mounting instructions. Use stainless steel hardware and anti-corrosion treatments during installation to maximize lifespan. If in doubt, consult a marine technician to ensure a proper fit.

Is the trim pump bracket compatible with all Mercruiser models?

While many trim pump brackets are universal in design, it’s important to verify compatibility with your specific Mercruiser engine model — particularly the Alpha One Gen I series. The Trim Pump Mounting Bracket Assembly is specifically built to match this model series. Using the wrong bracket can lead to misalignment or hydraulic issues. Always check product specifications or consult with the supplier before purchasing. A correctly matched bracket ensures seamless installation and peak trim pump performance.

How long does a marine trim pump mounting bracket last?

A high-quality marine trim pump bracket can last anywhere from 5 to 10 years, depending on usage and environmental exposure. Saltwater conditions and lack of maintenance can shorten its lifespan, while freshwater use and regular inspections extend it. Powder-coated or stainless steel brackets tend to last longer due to better corrosion resistance. Periodic cleaning and tightening of fasteners also help maintain the bracket’s performance over time. Keeping your trim system in top shape ensures smoother rides and fewer repairs down the line.

Conclusion

In the world of marine engine components, small parts like the trim pump mounting bracket assembly play a big role. Ensuring your hydraulic trim pump is mounted securely not only enhances performance but also protects your system from avoidable damage. Whether you’re installing a new bracket or replacing a worn-out one, always opt for high-quality components specifically designed for your engine model.

Don’t leave your trim pump at risk — invest in a trusted mounting solution today.

Special Offer

WELCOME5 – Get 5% off storewide at allboatsupplies.com

🚀 Instant Assistance: Need help selecting the right product? Drop your contact in the chatbox at the bottom right corner, and our expert team will reply within 30 minutes with the best product suggestion for your boat — including a ready-to-use checkout link. We’re fast, knowledgeable, and always here for your boating needs!

No more guesswork — just message us and get a personalized checkout link for your antifouling system, fast!

Explore Our Best-Selling Ultrasonic Antifouling Products:

Buy now

Trim Pump Mounting Bracket Assembly

Let us handle the hassle — expert support, quick replies, and smooth checkout. Your boat deserves the best.

Read More

For more helpful marine maintenance guides, check out our article on Roller Bearing Kit for Press Fit Gears.