Weld Mount Fastener Kit for Boats – Strong & Easy Mounting

Introduction

The Weld Mount Fastener Kit is a revolutionary solution for anyone looking to install or mount equipment inside boats and marine engines without the hassle of drilling or welding. Engineered specifically for marine environments, the Weld Mount AT-7001 Industrial Fastener Kit eliminates the risk of corrosion, water intrusion, and structural weakening caused by conventional mounting systems. It enables easy installation of electrical accessories, lighting systems, panels, conduits, and more using a proprietary adhesive-based bonding method.

This marine-grade fastener system has gained popularity among boatbuilders, professional technicians, and DIY enthusiasts for its quick setup, versatility, and incredible holding strength in harsh marine conditions. Whether you’re working on fiberglass, metal, or composite surfaces, the AT-7001 offers the ideal solution for secure, long-lasting installations without damaging the boat’s hull or interior.

Overview / What Is Weld Mount Fastener Kit

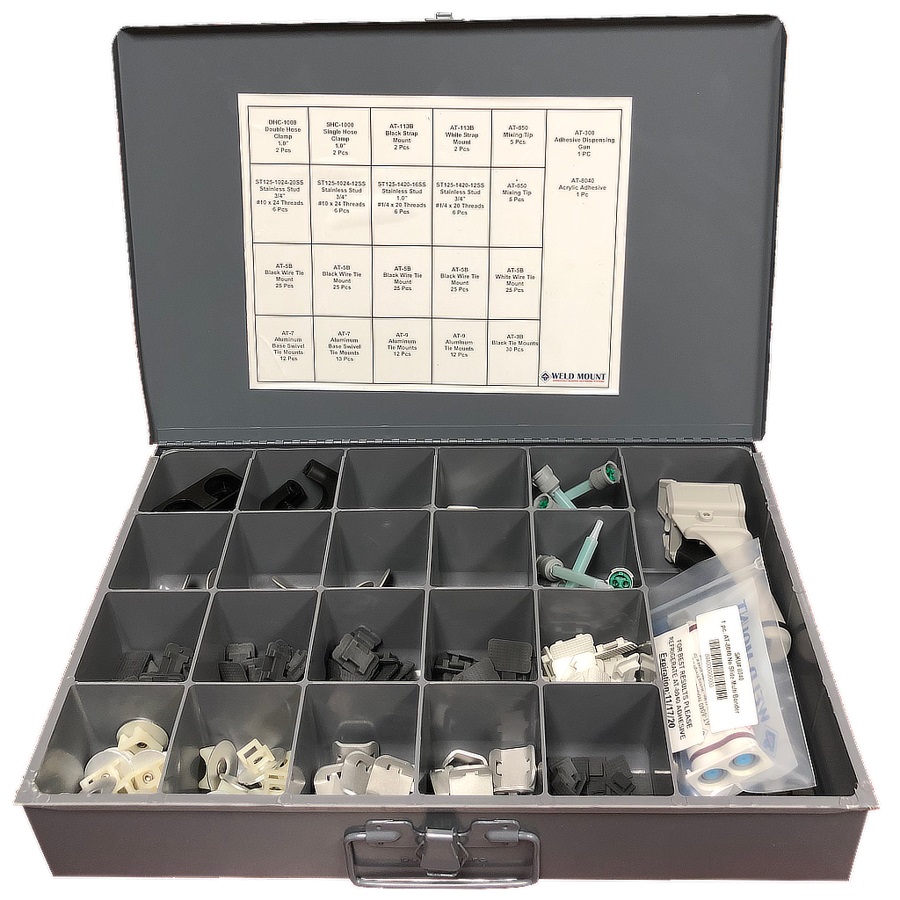

The Weld Mount AT-7001 Industrial Fastener Kit is a complete mounting solution designed to bond fasteners, cable tie mounts, and brackets to a variety of marine surfaces without mechanical penetration. The system includes an assortment of stainless steel studs, wire tie mounts, grounding fasteners, and a specially formulated acrylic adhesive designed to cure quickly and securely—even in high-humidity marine environments.

It’s a robust and versatile kit ideal for installing lighting, routing electrical wiring, fastening battery boxes, and more—without using rivets or screws. Because the mounts are adhesively bonded, there is no need for back access or bolt-through holes, preserving the vessel’s structural integrity and protecting it from future leaks and corrosion.

Applications: How to Use Weld Mount Fastener Kit

One of the primary advantages of the Weld Mount Fastener Kit is its wide range of applications onboard. Here are some of the most common uses:

- Mounting electrical junction boxes or switches inside engine compartments

- Routing cable and wire bundles along bulkheads or under decks

- Securing lighting systems on fiberglass or metal panels

- Installing battery trays without drilling through the floor

- Attaching plumbing brackets and conduit clamps inside cabinets or under gunwales

Because of the kit’s flexible bonding capability, it works equally well on aluminum, fiberglass, carbon fiber, PVC, and painted surfaces. It’s especially useful in tight or inaccessible areas where mechanical fastening is difficult or impossible.

Key Features and Benefits

The Weld Mount AT-7001 Fastener Kit provides several important features that make it a superior alternative to traditional fastening systems for boats:

- Drill-Free Installation: No holes mean no leaks or structural damage.

- Corrosion Resistant: Marine-grade stainless steel and nylon components resist rust and degradation.

- High Tensile Strength: Supports loads up to 200 lbs when used correctly with compatible adhesive.

- Quick Setup: Adhesive sets in minutes and fully cures in hours.

- Flexible Applications: Works on vertical, overhead, and irregular surfaces.

This combination of features makes the Weld Mount AT-7001 Fastener Kit an indispensable tool for both initial installations and retrofitting existing vessels.

Weld Mount Fastener Kit Cost and Durability

The value of the Weld Mount Fastener Kit lies not only in its long-term durability but also in the cost savings it offers by eliminating labor-intensive tasks such as drilling and welding. Additionally, it prevents potential repair costs caused by leaks, corrosion, or weakened structures due to mechanical fasteners.

Each fastener in the kit is engineered for durability. The acrylic adhesive resists water, heat, vibration, and UV radiation. Once bonded, the mounts remain stable and secure even after prolonged exposure to the harshest saltwater environments, ensuring long-term reliability and peace of mind.

Maintenance Tips

To ensure your Weld Mount Fastener Kit installations stay strong and reliable over time, follow these simple maintenance tips:

- Regular Inspections: Examine all mounts quarterly for wear, stress fractures, or environmental degradation.

- Load Checks: Avoid overloading mounts beyond their rated weight capacity. Distribute heavier items over multiple mounts.

- Surface Cleaning: Wipe mounts clean with a soft cloth and marine-safe cleaner to prevent buildup of grime or salt deposits.

- Timely Repairs: If a mount detaches or cracks, remove the old adhesive fully and re-bond a new mount with fresh adhesive.

With proper care, Weld Mount fasteners can outlast mechanical systems, especially in high-moisture marine environments.

Expert Advice and Pro Recommendations

Professionals in the marine industry recommend using the Weld Mount Fastener Kit in scenarios where traditional drilling could compromise boat integrity or when rapid installation is necessary. For example, in race boats or custom builds, weight reduction and watertightness are crucial—making this kit an ideal solution.

Marine electricians especially favor the AT-7001 kit for routing wiring securely without running risk of short circuits or chafing. Its vibration resistance and tight bonding also make it reliable for engine room use. Choose the appropriate adhesive version (fast cure, high-temp, or general purpose) for specific environmental conditions.

Buy now: Weld Mount AT-7001 Industrial Fastener Kit and use code WELCOME5 to receive 5% off your purchase today.

How to Install Weld Mount Fastener Kit

Installing your Weld Mount Fastener Kit correctly is essential for long-term performance. Here’s a quick guide:

- Clean the surface thoroughly using isopropyl alcohol or acetone to remove contaminants.

- Lightly scuff smooth surfaces with sandpaper to improve adhesive bonding.

- Apply adhesive to the base of the fastener generously and press it firmly into position.

- Secure with tape or clamps until adhesive sets (approximately 10-30 minutes depending on formula).

- Let cure for full strength (typically 4–6 hours before applying full load).

Always follow the adhesive manufacturer’s instructions and environmental guidelines. Temperature, humidity, and surface type all impact the final bond quality.

Weld Mount Fastener Kit Troubleshooting

Encountering issues with your fastener installation? Here are some common troubleshooting scenarios:

- Mount not sticking? Ensure the surface was thoroughly cleaned and roughed up prior to bonding. Moisture or oil can compromise adhesion.

- Fastener failure under load? You may be exceeding the recommended weight limit or the adhesive did not fully cure. Reinstall using proper cure time.

- Adhesive hardening too slowly? Check ambient temperature. Cold or high humidity environments will slow down the curing process.

Pro tip: Store your adhesive in a cool, dry place and keep the nozzle sealed tightly after use to maintain shelf life. For critical applications, do a trial bond on scrap material first.

Detailed FAQ Section

What comes in the Weld Mount AT-7001 Fastener Kit?

The Weld Mount AT-7001 Fastener Kit includes a mix of stainless steel threaded studs, plastic wire tie mounts, grounding pads, bonding brackets, and the required adhesive. Some kits may also include accessories like applicator tips, sandpaper, or alcohol wipes depending on the model. This variety allows users to tackle multiple types of installations—electrical, lighting, structural—on one or multiple vessels. Be sure to check the product listing for a detailed contents list before ordering.

Is the Weld Mount Kit safe for high-temperature areas?

Yes, but it depends on the adhesive you choose. The AT-6030 adhesive (not included by default) is specially formulated for high-temperature environments like engine compartments or near inverters. The base adhesive included in most AT-7001 kits works well up to moderate temperatures, but for extreme conditions above 200°F, you should upgrade to a high-temp variant. This ensures the bond remains stable and the fastener holds under thermal stress.

How long does the Weld Mount adhesive take to cure?

The standard acrylic adhesive included in the Weld Mount Fastener Kit sets within 10–30 minutes, depending on temperature and humidity. Full cure typically occurs within 4–6 hours. Faster-setting adhesives like the AT-8040 may reduce curing time to just 10 minutes. For maximum bond strength, avoid applying load until the adhesive has cured completely. Always read the label and follow cure times precisely, especially in colder climates or high-humidity environments.

Can I use this kit on fiberglass boats?

Absolutely. The Weld Mount Fastener Kit is perfectly compatible with fiberglass surfaces, which are common in most recreational and fishing boats. Clean the surface well, roughen slightly with sandpaper, and use the recommended adhesive. Since fiberglass can be brittle, not drilling is a major advantage. Adhesively bonded mounts are also less likely to cause cracking or delamination over time. Always choose the right fastener for the load requirement and application area.

Is the Weld Mount system better than traditional drilling?

In many cases, yes. The Weld Mount Fastener Kit provides secure, long-lasting bonds without damaging the structural integrity of the boat. It eliminates the risk of through-hull leaks, corrosion from metal screws, and the labor involved in drilling holes. However, for very heavy equipment or permanent engine mounts, mechanical fasteners may still be required. Use the Weld Mount kit wherever a lightweight, non-penetrating solution is ideal—especially in electrical and lighting systems onboard.

Conclusion

The Weld Mount Fastener Kit is a smart investment for any boat owner or marine technician. Its innovative adhesive bonding system provides a clean, corrosion-proof, and damage-free method of mounting all kinds of onboard equipment. From ease of use to exceptional durability, it redefines how professionals and DIYers approach electrical and lighting installation in marine settings. For high-performance, low-maintenance marine mounting—Weld Mount leads the way. Explore more reliable marine gear at Yamaha Outboards.

Special Offer

WELCOME5 – Get 5% off storewide at allboatsupplies.com

🚀 Instant Assistance: Need help selecting the right product? Drop your contact in the chatbox at the bottom right corner, and our expert team will reply within 30 minutes with the best product suggestion for your boat — including a ready-to-use checkout link. We’re fast, knowledgeable, and always here for your boating needs!

No more guesswork — just message us and get a personalized checkout link fast!

Let us handle the hassle — expert support, quick replies, and smooth checkout. Your boat deserves the best.

🔥 Up to 5% OFF – Limited Time!

Use code WELCOME5 on Weld Mount AT-7001 Industrial Fastener Kit

Read More

For more helpful marine maintenance guides, check out our article on Weld Mount SS Stud – Durable & Hassle-Free Marine Mount.