Weld Mount SS Stud – Best & Worst Aspects Explained

Introduction

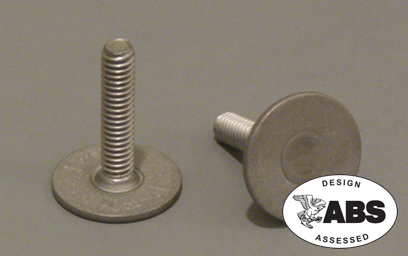

The Weld Mount SS Stud — specifically the Weld Mount 1.50″ Tall #8 x 32 PS62-832-24SS SS Stud 0.62″ Base 15 Pack — is an essential marine-grade installation accessory designed for the rigorous demands of boat and marine engine environments. Built from premium stainless steel and engineered to integrate with structural adhesives, this mounting stud stands out for its easy installation, high tensile strength, and corrosion resistance. Whether you’re upgrading an electrical system, rigging a new power setup, or retrofitting lighting components, this product is your go-to solution.

In marine environments where vibration, moisture, and saltwater exposure are constant threats, traditional mechanical fasteners often fall short. Enter the Weld Mount SS Stud — a reliable adhesive-based solution that eliminates the need for drilling, welding, or tapping. These studs are designed to adhere securely to fiberglass, metal, and other substrates using Weld Mount adhesives.

Overview / What Is Weld Mount SS Stud

The Weld Mount SS Stud is a stainless steel mounting post intended to be bonded to surfaces using acrylic adhesives. The PS62-832-24SS model is 1.50 inches tall with a #8 x 32 thread and a 0.62-inch diameter base, perfect for managing heavy-duty marine and electrical applications.

These studs come in a 15-pack, offering value and readiness for complex or large-scale installations. They’re ideal for securing electrical panels, wire clamps, terminal blocks, and more — without compromising the hull or other vital marine components with holes or welds.

Key Benefits of Weld Mount SS Stud for Marine Use

Below are some standout features of this stud model:

- High Corrosion Resistance: Built from 316 stainless steel, these studs resist rust and degradation in saltwater conditions.

- Non-Penetrating Mounting: Avoid holes in your boat’s structure — great for waterproofing and maintaining hull integrity.

- Time-Saving Install: Use in conjunction with Weld Mount adhesives like AT-8040 for a quick and permanent bond.

- Universal Application: Works well on fiberglass, metal, plastic, and composite materials.

How to Install Weld Mount SS Stud

Installing the Weld Mount SS Stud involves a few simple steps:

- Clean the surface thoroughly using acetone or Weld Mount Surface Prep solution.

- Mark the mounting location and ensure proper stud alignment.

- Apply Weld Mount adhesive such as AT-8040 to the base.

- Press the stud firmly in place and hold for a few seconds.

- Allow curing time as per adhesive instructions (typically 10–20 minutes).

This non-mechanical installation ensures a secure fit without risking structural damage.

Common Applications of Weld Mount SS Stud in Boats

When working on boats or marine engines, the use of Weld Mount SS Stud opens a world of applications, such as:

- Mounting electrical junction boxes

- Securing battery trays and holders

- Anchoring fuel and hydraulic lines

- Affixing terminal strips and grounding blocks

The ability to bond without drilling is especially beneficial for high-end vessels, where cosmetic and structural integrity are paramount.

Maintenance Tips

Although the Weld Mount SS Stud requires minimal upkeep once installed, these tips will help ensure long-term performance:

- Inspect bonding areas every six months for signs of stress or adhesive degradation.

- Use marine-grade sealants to reinforce bonds in high-vibration zones.

- Replace any studs showing corrosion or impact damage.

Proper maintenance reduces the risk of detachment and enhances onboard safety.

Expert Advice and Pro Recommendations

Marine electricians and boatbuilders frequently recommend using Weld Mount SS Studs for projects involving hidden wiring, lighting fixtures, and customized power setups. Compared to screw-mounted systems, adhesive studs reduce labor time and avoid cosmetic damage.

For best results, pair the Weld Mount SS Stud with an adhesive like AT-8040. Ensure the workspace is well-ventilated and above 60°F during curing. Buy now and save 5% using code WELCOME5: Weld Mount 1.50″ Tall #8 x 32 PS62-832-24SS SS Stud 0.62″ Base 15 Pack

Weld Mount SS Stud Troubleshooting Tips

Even with the right adhesive, improper prep or installation can cause issues. Common problems include:

- Stud Falling Off: Usually due to inadequate surface prep. Always clean with alcohol or acetone.

- Uneven Bonding: Ensure even pressure during the initial bonding period.

- Delayed Cure Time: Temperature or humidity may be slowing the process. Use heat lamps or warm the adhesive beforehand.

Still facing issues? You can find more guidance from the experts at Yamaha Outboards.

Weld Mount SS Stud Cost and Durability Comparison

Compared to traditional mounts and clamps, the Weld Mount SS Stud offers a lower lifetime cost thanks to:

- Reduced installation labor

- Fewer replacements needed

- Superior longevity and resistance to marine wear

Although the upfront price may be slightly higher, the durability of stainless steel ensures you won’t be replacing mounts every season.

Detailed FAQ Section

What surfaces can I mount the Weld Mount SS Stud onto?

The Weld Mount SS Stud is designed for maximum adhesion to a wide variety of surfaces commonly found in marine and electrical environments. These include fiberglass, painted or unpainted aluminum, composite materials, and carbon fiber. For optimal results, ensure the surface is clean, dry, and free from oils or debris. Surface preparation with Weld Mount Surface Prep or isopropyl alcohol is highly recommended. Avoid using the studs on oily plastics like polyethylene or surfaces that are heavily waxed without thorough preparation.

How strong is the bond created with Weld Mount SS Stud and adhesive?

When used with the correct adhesive like AT-8040 or AT-6030, the Weld Mount SS Stud creates an extremely strong bond that can withstand tensile loads upwards of 500 pounds. The key lies in proper surface preparation and allowing the adhesive to cure fully as instructed. It’s suitable for high-vibration environments such as engine compartments and electrical panels. Always allow full cure time and test the bond before applying stress or torque.

Can I remove or reposition a Weld Mount SS Stud once installed?

Removing a bonded Weld Mount SS Stud can be challenging. If necessary, apply a heat gun to the base to soften the adhesive. Carefully pry the stud off using a chisel or flathead screwdriver. Reinstallation at a new spot requires fully cleaning the original adhesive and repeating the bonding process with new adhesive. Reusing the old adhesive or residue is not recommended as it may compromise the bond strength.

Is the Weld Mount SS Stud suitable for underwater use?

While the Weld Mount SS Stud is made from corrosion-resistant stainless steel and can handle wet environments, it is not designed for direct, long-term submersion. The bonding adhesive’s performance underwater is limited and may degrade over time. For below-the-waterline or submerged installations, consult marine-grade epoxy or use mechanical mounts certified for submerged conditions.

How does the Weld Mount SS Stud compare to screw or bolt installations?

The main advantage of using the Weld Mount SS Stud over mechanical fasteners is the preservation of structural integrity. No drilling means no risk of water intrusion, hull weakening, or cracking. It also allows for precise placements in tight or curved spaces where tools cannot reach. Additionally, adhesive-mounted studs create clean, professional installations — a must for high-end yachts or showboats. Overall, it offers better aesthetics, quicker installation, and long-term reliability.

Conclusion

Whether you’re rewiring a boat, installing a new lighting system, or reinforcing engine mounts, the Weld Mount SS Stud is your go-to solution. With its strong hold, stainless steel durability, and ease of installation, it outperforms traditional fastening methods in both convenience and reliability. It’s the marine installer’s best-kept secret for durable, corrosion-resistant solutions in the most challenging environments.

Special Offer

WELCOME5 – Get 5% off storewide at allboatsupplies.com

🚀 Instant Assistance: Need help selecting the right product? Drop your contact in the chatbox at the bottom right corner, and our expert team will reply within 30 minutes with the best product suggestion for your boat — including a ready-to-use checkout link. We’re fast, knowledgeable, and always here for your boating needs!

No more guesswork — just message us and get a personalized checkout link fast!

Let us handle the hassle — expert support, quick replies, and smooth checkout. Your boat deserves the best.

🔥 Up to 5% OFF – Limited Time!

Use code WELCOME5 on Weld Mount 1.50″ Tall #8 x 32 PS62-832-24SS SS Stud 0.62″ Base 15 Pack

🚀 Buy Now – Weld Mount 1.50″ Tall #8 x 32 PS62-832-24SS SS Stud 0.62″ Base 15 Pack

Read More

For more helpful marine maintenance guides, check out our article on Weld Mount AT-5 Mount Large Black 30 Pack – Best & Worst Use Cases.