Weld Mount SS Stud Best & Worst Use Cases

Weld Mount 1.50″ Tall #10 x 24 ST125-1024-24SS SS Stud 1.25″ Base 10 Pack for Boats & Marine Engines

Introduction

The Weld Mount 1.50″ Tall #10 x 24 ST125-1024-24SS SS Stud 1.25″ Base 10 Pack for Boats & Marine Engines is a premium-grade, corrosion-resistant stainless steel mounting solution engineered for the harsh marine environment. Whether you’re outfitting a new vessel or retrofitting an older boat, this stud kit provides the strength, longevity, and ease of installation that marine professionals demand. Its no-drill technology ensures structural integrity while delivering fast and efficient setups.

This article dives into everything you need to know about the Weld Mount SS Stud, from features and applications to expert recommendations and FAQs. It is categorized under Electrical & Lighting > Electrical > Installation Accessories, making it an essential addition to any marine electrical toolkit.

Overview / What Is Weld Mount SS Stud

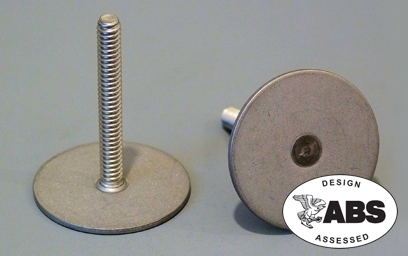

The Weld Mount SS Stud is part of the revolutionary Weld Mount System, which allows for secure, adhesive-based mounting without drilling holes into your boat’s hull or panels. Designed specifically for marine applications, the ST125-1024-24SS studs are made from stainless steel, measuring 1.50″ tall with a 1.25″ base and threaded for #10 x 24 screws. Each 10-pack offers dependable mounting performance even under intense vibration and corrosive saltwater conditions.

Whether you’re installing cable clamps, electrical panels, or mounting engine accessories, this stud kit supports diverse applications with reliable results. The unique adhesive bonding system adheres to fiberglass, metal, or plastic surfaces, reducing labor time and improving structural preservation.

Key Features of the Weld Mount SS Stud

- 1.50″ tall, #10 x 24 thread size – compatible with standard marine hardware

- High-strength 316 stainless steel construction – rust-resistant and marine-grade

- 1.25″ base diameter for a firm grip and large bonding surface

- Adhesive mount – no drilling required, preserving surface integrity

- 10 pack – ideal for bulk installations or maintenance kits

This versatile kit is trusted by professional boatbuilders and DIY enthusiasts alike for everything from wiring projects to structural component attachment. With fast curing adhesives like AT-8040 or AT-4020, these studs set quickly and bond permanently.

Applications of Weld Mount SS Studs in Marine Projects

The Weld Mount SS Stud is more than just a stud—it’s a multipurpose solution for boats of all sizes. It is used in:

- Engine Bay Mounting: Secure wiring looms, engine covers, and auxiliary electronics without drilling into metal panels.

- Deck Hardware Installation: Mount small fixtures like navigation lights or speakers.

- Cabin Retrofitting: Add cabinetry supports, panel covers, or overhead components.

Its adhesive-mounted base allows you to place studs where traditional mounting hardware would be impractical or impossible. With no corrosion, vibration loosening, or electrolysis concerns, these studs offer lasting peace of mind.

How to Install Weld Mount SS Stud

Installing the Weld Mount SS Stud is straightforward with the right adhesive and preparation. Follow these steps for a successful application:

- Clean the mounting surface thoroughly to remove grease, dust, or oxidation.

- Use Weld Mount-approved adhesives like AT-8040 for quick bonding or AT-4020 for general use.

- Apply adhesive to the base and press the stud firmly into place.

- Hold in position for 60 seconds or until adhesive begins to set.

- Allow curing time (up to 24 hours depending on adhesive) before loading the stud.

Ensure temperatures and humidity are optimal during installation for the best results. Once installed, the stud offers heavy-duty holding power.

Maintenance Tips

Although the Weld Mount SS Stud requires minimal maintenance, following these tips will ensure long-lasting performance:

- Inspect Regularly: Check for signs of adhesive breakdown or excessive vibration movement.

- Clean Around Studs: Use a mild marine-safe cleaner to prevent salt or dirt build-up.

- Avoid Overloading: Respect the weight limits per stud to prevent structural damage.

- Check Adhesive Seal: If exposed to high-pressure washing, verify that bonding remains intact.

With basic upkeep, these studs can last as long as the boat itself, even in harsh offshore environments.

Expert Advice and Pro Recommendations

Marine electricians and engine installers consistently rate the Weld Mount SS Stud as one of the best installation accessories for its ease of use and high reliability. Here are some professional insights:

- Always pair with Weld Mount-recommended adhesives for warranty-compliant installation.

- Use masking tape to mark positions before bonding to ensure precise alignment.

- For underwater or wet environments, apply extra bonding agent and ensure full curing time.

Buy now: Weld Mount 1.50″ Tall #10 x 24 ST125-1024-24SS SS Stud 1.25″ Base 10 Pack and get 5% off with code WELCOME5.

Cost and Durability of Weld Mount SS Stud

In terms of cost-efficiency, the Weld Mount SS Stud outperforms traditional mounting hardware. With minimal tools, reduced installation time, and zero drilling damage, it offers long-term savings for boat owners. Its 316 stainless steel ensures resistance to corrosion, wear, and heavy loads.

This makes it a reliable, cost-effective investment for both new builds and ongoing marine maintenance. Whether you’re outfitting a commercial yacht or a weekend cruiser, durability is guaranteed.

Comparing Weld Mount Studs with Traditional Mounting Hardware

Traditional mounts often involve drilling, bolting, or riveting, which can compromise your boat’s hull integrity and aesthetics. In contrast, the Weld Mount SS Stud uses high-strength adhesive to create a bond that is equally strong—without the need for holes or reinforcements.

This stud system reduces weight, installation time, and potential water ingress points. Professionals appreciate its no-drill approach, especially for retrofitting modern accessories on classic boats. Yamaha Outboards also recommends modern installation methods for efficiency and safety.

Detailed FAQ Section

How much weight can each Weld Mount SS Stud hold?

Each Weld Mount SS Stud is engineered to hold approximately 250 lbs of tensile load when used with the correct adhesive and applied on a clean, flat surface. However, performance can vary depending on bonding material, surface condition, and curing time. It’s recommended to follow adhesive guidelines and avoid over-torquing to maintain maximum load capacity.

Is the Weld Mount SS Stud suitable for underwater applications?

Yes, with proper installation and curing, the Weld Mount SS Stud can be used in underwater or high-humidity environments. However, it’s essential to use a marine-grade adhesive like AT-4020 or AT-6030 that is specifically formulated for submerged conditions. Always ensure full curing before exposure to water for maximum bond integrity.

Can I use Weld Mount SS Studs on curved surfaces?

The 1.25″ base is best suited for flat surfaces, but can accommodate slight curves depending on the adhesive’s gap-filling ability. For significantly curved surfaces, prep the area thoroughly and use an adhesive that can bond uneven textures. Use clamps or tape to secure during curing to maintain full surface contact.

What tools do I need to install the Weld Mount SS Stud?

No heavy tools are required. You’ll need a clean cloth, surface cleaner (isopropyl alcohol), the correct Weld Mount adhesive, and optional clamps or masking tape. The installation process is simple and tool-free, saving time and labor costs compared to traditional mounting systems.

How long does it take for the adhesive to cure?

Curing times depend on the adhesive used. For AT-8040 (fast-set adhesive), studs will cure in under 5 minutes. For more general applications using AT-4020, expect full cure within 24 hours. Always avoid loading the stud before full curing to maintain strength and ensure long-term durability.

Conclusion

The Weld Mount 1.50″ Tall #10 x 24 ST125-1024-24SS SS Stud 1.25″ Base 10 Pack for Boats & Marine Engines offers unparalleled performance, ease of use, and durability for all marine applications. With its innovative adhesive-based mounting system and stainless steel design, it’s built to thrive in the demanding conditions of marine environments. Whether you’re a DIY boater or a professional marine technician, this product delivers value, safety, and reliability every time.

Special Offer

WELCOME5 – Get 5% off storewide at allboatsupplies.com

🚀 Instant Assistance: Need help selecting the right product? Drop your contact in the chatbox at the bottom right corner, and our expert team will reply within 30 minutes with the best product suggestion for your boat — including a ready-to-use checkout link. We’re fast, knowledgeable, and always here for your boating needs!

No more guesswork — just message us and get a personalized checkout link fast!

Let us handle the hassle — expert support, quick replies, and smooth checkout. Your boat deserves the best.

🔥 Up to 5% OFF – Limited Time!

Use code WELCOME5 on Weld Mount 1.50″ Tall #10 x 24 ST125-1024-24SS SS Stud 1.25″ Base 10 Pack

🚀 Buy Now – Weld Mount 1.50″ Tall #10 x 24 ST125-1024-24SS SS Stud 1.25″ Base 10 Pack