Propellers for a Dual-Engine Setup

Introduction

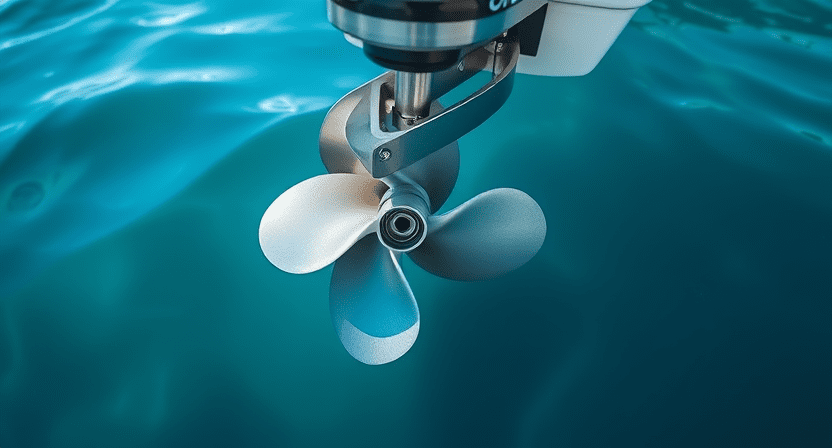

Choosing the right propellers for a dual-engine setup can significantly impact your boat’s performance, fuel efficiency, and handling. The wrong propeller may lead to reduced speed, poor fuel economy, and engine strain. This guide will explore which propeller works best with dual-engine setups, focusing on boat propellers, outboard lower units, and key considerations for achieving optimal performance.

In this guid you will get to know how to add Propellers for a Dual-Engine Setup in you boat;s inventory .

Why Dual-Engine Setups Require Special Propellers

Dual-engine boats are designed for power, speed, and redundancy. The propellers in such setups must synchronize efficiently with the engines to balance thrust and prevent unnecessary drag. The unique demands of dual engines make the selection of the right propeller crucial.

Key benefits of using the right propeller:

- Improved Efficiency: Properly sized propellers reduce fuel consumption.

- Enhanced Handling: Balanced thrust enhances steering control.

- Prolonged Engine Life: Reduces wear on the outboard lower unit and engine components.

Factors to Consider When Choosing a Propeller for Dual-Engine Setups

1. Propeller Size and Pitch

The size and pitch of a propeller affect speed and engine load. For dual-engine setups:

- Diameter: Larger diameters provide more thrust, ideal for heavier boats.

- Pitch: Lower pitches increase acceleration, while higher pitches maximize top speed.

2. Material: Aluminum vs. Stainless Steel

- Aluminum Propellers: Affordable and lightweight, suitable for casual boating.

- Stainless Steel Propellers: Durable and efficient, perfect for high-performance needs.

3. Blade Count

- Three-Blade Propellers: Excellent for speed and general use.

- Four-Blade Propellers: Ideal for heavy loads and stability.

- Specialty Propellers: For unique setups like shallow waters or high-speed boats.

4. Compatibility with Outboard Lower Units

A dual-engine boat’s outboard lower unit must match the propeller type for optimal performance. Ensure that the propeller fits securely and rotates correctly for both engines.

5. Counter-Rotating Propellers

Dual-engine setups often use one standard rotation and one counter-rotating propeller to maintain balance. This setup reduces torque steer and enhances maneuverability.

Best Propellers for Dual-Engine Setups

1. Mercury Revolution 4

- Best For: Heavy boats requiring stability.

- Features: Four-blade design, stainless steel construction, and excellent mid-range performance.

- Ideal Use: Offshore fishing boats and cruisers.

2. Yamaha Saltwater Series II

- Best For: Saltwater applications.

- Features: Durable stainless steel build, high thrust, and corrosion resistance.

- Ideal Use: Dual-engine setups for long trips.

3. Solas Rubex HR4

- Best For: High-speed boats.

- Features: Four-blade design, enhanced acceleration, and reduced vibration.

- Ideal Use: Sport boats and dual-engine pontoons.

4. Michigan Wheel Apollo

- Best For: Versatility across different water conditions.

- Features: Stainless steel, customizable pitch options, and high durability.

- Ideal Use: Recreational dual-engine boats.

Tips for Maximizing Dual-Engine Propeller Performance

1. Match Propeller Sizes

Using mismatched propellers can cause unbalanced thrust and reduced performance. Always pair identical propeller models and sizes for dual-engine setups.

2. Perform Regular Maintenance

Inspect the boat propellers and outboard lower units regularly for damage or wear. Replace damaged propellers promptly to avoid engine strain.

3. Use a Propeller Calculator

A boat propeller calculator helps determine the ideal size and pitch based on your boat’s weight, engine power, and usage.

4. Test for Optimal RPM

Test your propellers to ensure the engines operate within the recommended RPM range. Adjust pitch or diameter if necessary.

Common Propeller Issues and Repairs

1. Damaged Blades

Propeller blades can bend or chip due to debris or impact.

Solution: File minor damages or replace severely damaged blades.

2. Cavitation

Cavitation occurs when air bubbles form around the propeller, reducing efficiency.

Solution: Use a propeller with proper pitch and ensure the outboard lower unit is correctly aligned.

3. Corrosion

Saltwater can corrode propellers over time.

Solution: Opt for stainless steel propellers and rinse with freshwater after each use.

Frequently Asked Questions

1) How to change a boat propeller?

- Remove the propeller nut using a wrench.

- Slide off the old propeller and inspect for damage.

- Grease the propeller shaft and install the new propeller.

- Secure with a washer and nut, ensuring a tight fit.

2) How do you measure a boat propeller?

To measure a boat propeller:

- Measure the diameter by calculating the distance across the blade circle.

- Determine the pitch, which is the distance the propeller moves in one rotation.

3) How to change boat propeller?

Follow the steps outlined in the first FAQ. Ensure proper alignment and test the new propeller before heading out on the water.

4)How to measure a boat propeller?

Use a measuring tape or refer to the manufacturer’s specifications. Measure both diameter and pitch for accurate sizing.

5) How to size a boat propeller?

Consider the boat’s weight, engine power, and intended use. Use a boat propeller calculator or consult an expert for precise recommendations.