Choosing the Right Outboard Lower Unit

A Complete Guide to Choosing the Right Outboard Lower Unit

In this guide, we’ll explore everything you need to know about Choosing the Right Outboard Lower Unit, matching it with the right propeller, and maintaining it for long-term use.

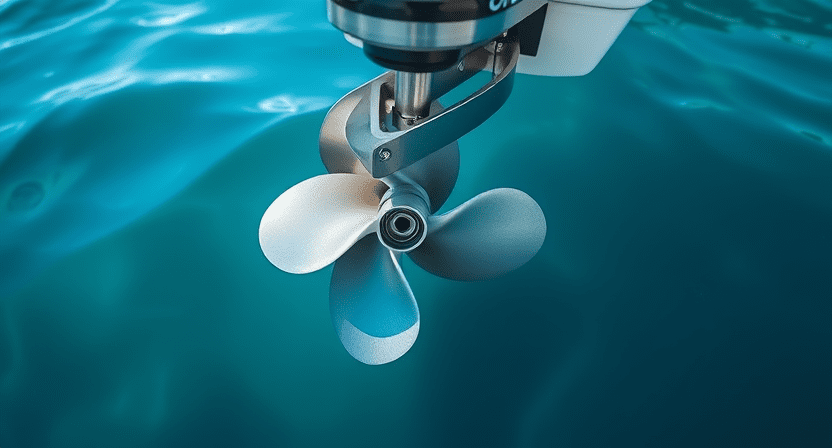

The outboard lower unit is one of the most crucial components of your boat’s engine. It serves as the connection between your engine and propeller, ensuring smooth navigation and optimal performance. Choosing the right outboard lower unit can significantly impact your boating experience, whether for fishing, leisure cruising, or watersports.

What Is an Outboard Lower Unit?

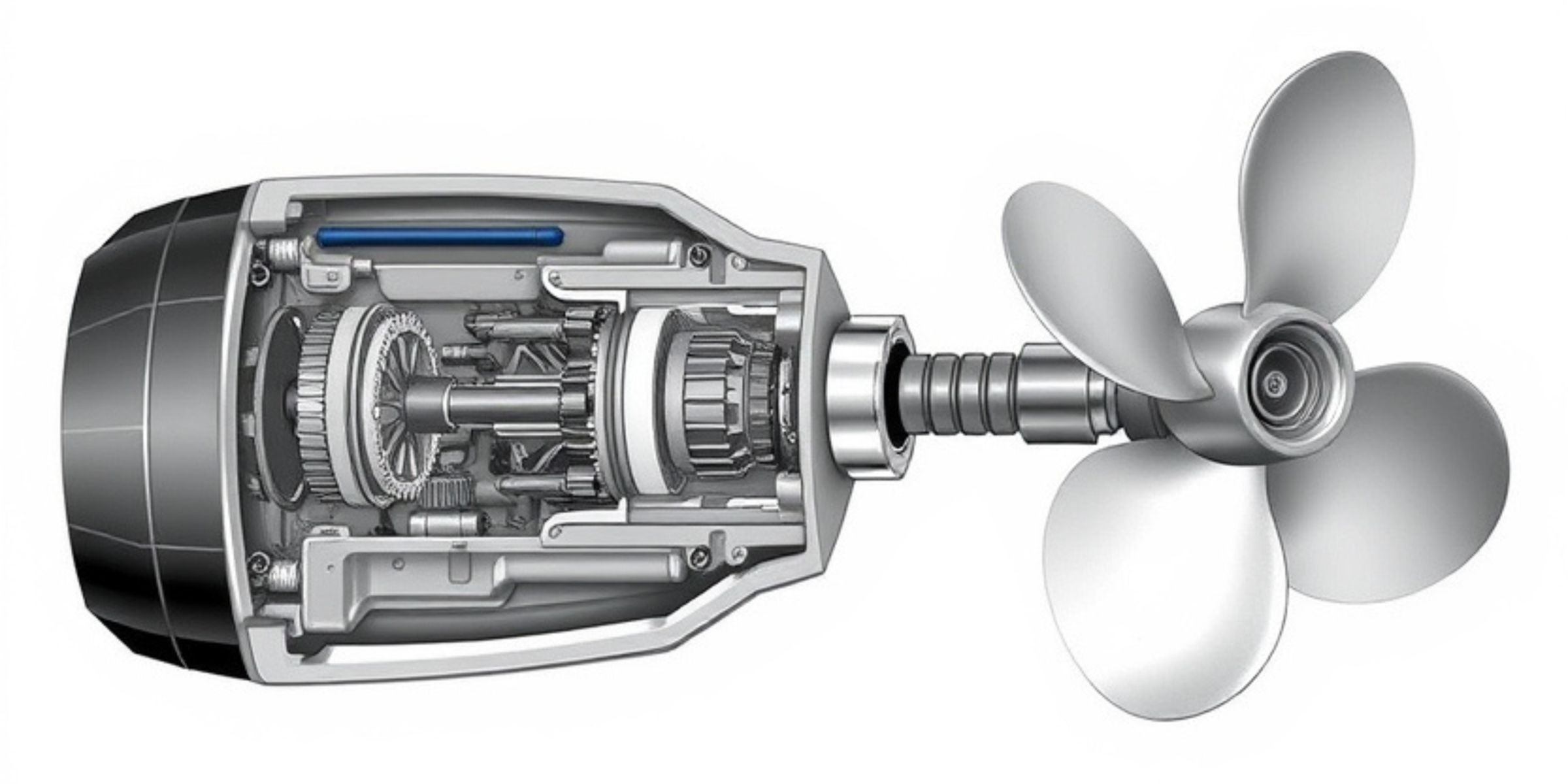

The outboard lower unit, often referred to as the gearcase, is located beneath the waterline and houses essential components such as gears, the driveshaft, and the propeller shaft. It’s responsible for transmitting power from the engine to the propeller, converting high-speed engine revolutions into thrust.

Factors to Consider When Choosing an Outboard Lower Unit

1. Compatibility with Your Boat and Engine

Ensure the lower unit is compatible with your outboard engine model. Manufacturer specifications typically outline the recommended lower unit for each engine type.

2. Gear Ratio

The gear ratio affects how efficiently power is transferred from the engine to the propeller. For heavy loads or larger boats, a lower gear ratio is better.

3. Material and Build Quality

Choose a lower unit made from durable materials like aluminum or stainless steel, especially for saltwater environments where corrosion is a concern.

4. Propeller Matching

The lower unit should work seamlessly with your propeller. A mismatched propeller can reduce efficiency and strain the engine.

Signs You Need a Replacement Lower Unit

1. Unusual Noise or Vibration

Grinding or vibrating sounds could indicate internal damage.

2. Leaking Gear Oil

Check for oil leaks near the gearcase, as these might signal a damaged seal.

3. Reduced Performance

If your boat struggles to reach its usual speed or efficiency, the lower unit might need inspection or replacement.

Outboard Lower Unit Maintenance Tips

1. Regular Inspection

Check the lower unit for cracks, corrosion, or wear, especially after extensive use.

2. Gear Oil Changes

Replace the gear oil annually or as specified by the manufacturer to prevent internal damage.

3. Avoiding Grounding

Steer clear of shallow waters or underwater obstacles to prevent impact damage.

Matching the Outboard Lower Unit with the Propeller

A correctly matched propeller improves fuel efficiency, speed, and overall performance. When choosing a propeller:

- Ensure the pitch and diameter suit your lower unit’s gear ratio.

- Use stainless steel propellers for better durability in harsh conditions.

- Opt for aluminum propellers for cost-effective performance on smaller boats.

Real-World Example: Choosing the Right Lower Unit

For instance, a 115-horsepower outboard engine requires a lower unit with the appropriate gear ratio to optimize its torque. If paired with a mismatched propeller, the boat might experience sluggish acceleration or increased fuel consumption.

Common Mistakes to Avoid

- Ignoring Manufacturer Guidelines: Always follow recommendations for your engine model.

- Using the Wrong Gear Oil: Incorrect oil can lead to internal wear and reduced lifespan.

- Neglecting Regular Maintenance: Overlooking routine checks can cause costly repairs.

Conclusion

Selecting the right outboard lower unit is essential for maintaining your boat’s performance and reliability. By considering factors like compatibility, gear ratio, and propeller matching, you can ensure smooth operation and longevity. Regular maintenance will further protect your investment, allowing you to enjoy countless worry-free boating adventures.

Related Content:

Check out our previous blog, “Understanding the Role of Hull Shields in Protecting Your Boat“, for more tips on safeguarding your vessel.