Maintain Outboard lower unit for Longevity

Introduction

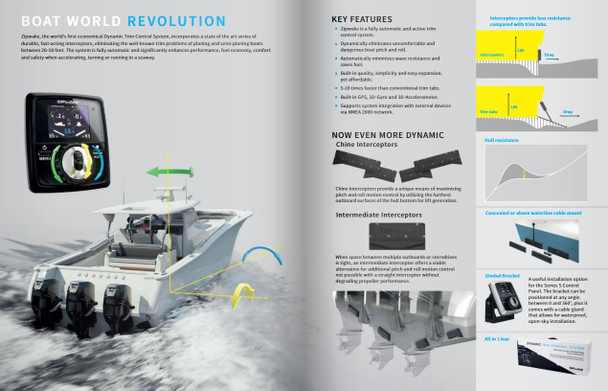

The outboard lower unit is one of the most critical components of your boat’s engine. Responsible for converting power into thrust, it plays a vital role in your boat’s overall performance. Regular maintenance ensures the longevity of your lower unit, reduces costly repairs, and improves boating safety. In this guide, we’ll cover essential tips on how to properly maintain your outboard lower unit, ensuring it stays in top condition for years to come.

Understanding the Outboard Lower Unit

1. What is the Outboard Lower Unit?

The outboard lower unit is the part of your engine located below the waterline. It includes key components such as the driveshaft, gears, water pump, and propeller. Together, they convert engine power into forward motion.

2. Why is Maintenance Important?

Neglecting lower unit maintenance can lead to:

- Reduced engine efficiency.

- Expensive repairs due to gear or propeller damage.

- Shortened lifespan of your marine engine.

3. Common Signs of Issues

Watch for the following signs that your lower unit needs attention:

- Unusual vibrations or noises.

- Difficulty shifting gears.

- Water contamination in the gear oil.

Essential Maintenance Tips for Your Outboard Lower Unit

1. Regular Gear Oil Changes

- Why It Matters: Gear oil lubricates the gears and prevents friction, ensuring smooth operation.

- How Often: Change the gear oil every 50-100 hours of use or at least once per season.

- Steps:

- Remove the drain plug and let the old oil drain.

- Inspect the oil for signs of water (milky color) or metal shavings.

- Refill with high-quality marine gear oil.

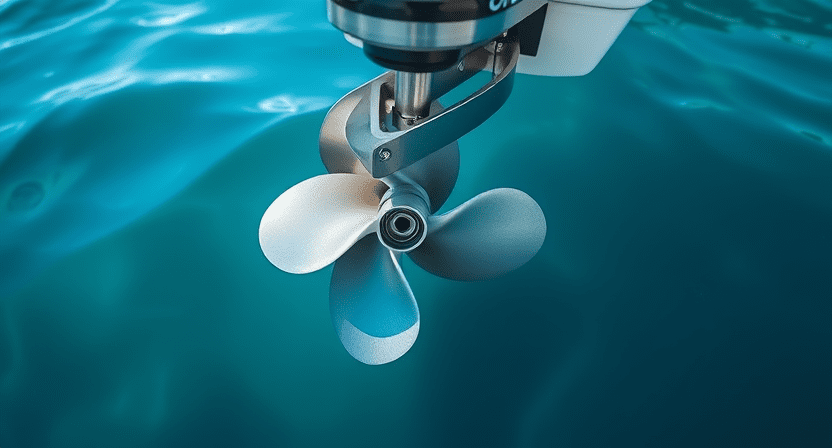

2. Inspect the Propeller Regularly

- Why It Matters: The propeller is directly connected to the lower unit and can impact its performance.

- Tips:

- Remove the propeller to check for fishing line or debris around the shaft.

- Inspect for dents or cracks that could cause imbalance.

- Apply grease to the propeller shaft to prevent corrosion.

3. Check and Replace Seals

- Why It Matters: Damaged seals can allow water to enter the lower unit, causing severe damage.

- How to Check:

- Look for oil leaks around the propeller shaft or drain plug.

- Replace worn or damaged seals promptly.

4. Clean the Water Intakes

- Why It Matters: Clogged water intakes can cause the engine to overheat, damaging the lower unit.

- Steps:

- Use a soft brush to clean the water intakes.

- Check for blockages after every trip, especially in shallow or muddy waters.

5. Inspect for Physical Damage

- Why It Matters: Impacts with underwater objects can crack or dent the lower unit.

- Steps:

- Visually inspect the lower unit for damage after each trip.

- If you suspect internal damage, consult a marine mechanic.

Advanced Tips for Maintaining Longevity

1. Use High-Quality Parts and Lubricants

- Opt for manufacturer-recommended gear oil and replacement parts to ensure optimal performance.

2. Store the Engine Properly

- After each boating season, store the engine in an upright position to prevent water from freezing inside the lower unit.

3. Flush the Engine After Use

- After boating in saltwater, flush the engine with freshwater to prevent salt buildup and corrosion.

4. Avoid Overloading Your Boat

- Excessive weight can strain the lower unit, causing premature wear and tear.

5. Schedule Professional Maintenance

- Have your engine professionally serviced annually to address issues you may have missed.

Common Mistakes to Avoid

1. Ignoring Small Issues

- Minor problems like strange noises or small leaks can escalate into major repairs if left unattended.

2. Overlooking Propeller Damage

- A damaged propeller can stress the lower unit, reducing its lifespan.

3. Using the Wrong Gear Oil

- Always use marine-specific gear oil designed for outboard engines.

4. Skipping Seasonal Maintenance

- Routine seasonal maintenance is crucial, even if your boat hasn’t been used extensively.

5. Operating in Shallow Waters Without Caution

- Rocks, sand, and debris in shallow water can damage the propeller and lower unit.

FAQs

1. How often should I maintain my outboard lower unit?

Perform basic checks after every trip, with full maintenance (gear oil change, propeller inspection) at least once per season or every 50-100 hours of use.

2. What are the signs of water in the gear oil?

Milky or cloudy gear oil indicates water contamination, which requires immediate attention.

3. Can I use automotive gear oil for my outboard lower unit?

No, always use marine-grade gear oil to ensure proper lubrication and protection.

4. How do I prevent corrosion in the lower unit?

Flush the engine after saltwater use and apply anti-corrosion sprays to vulnerable parts.

5. What should I do if my lower unit is damaged?

Stop using the engine immediately and consult a professional mechanic for repairs.

Conclusion

Properly Maintain outboard lower unit is essential for ensuring the longevity of your boat’s engine and overall performance. By following these tips—such as changing gear oil, inspecting the propeller, and checking seals—you can avoid costly repairs and enjoy smoother boating adventures. Routine maintenance not only extends the life of your lower unit but also ensures a safer and more efficient experience on the water.