Lower Unit Maintenance Checklist for Busy Boaters

Introduction

Your outboard motor’s lower unit is essential for smooth and efficient operation on the water. However, busy schedules can make it easy to overlook regular maintenance. That’s why having a clear lower unit maintenance checklist for busy boaters is crucial. This guide covers all the essential steps you need to follow to keep your outboard lower unit in optimal condition, save on costly repairs, and enjoy worry-free boating adventures.

Why Lower Unit Maintenance is Crucial

The lower unit is responsible for transferring power from the motor to the propeller. Neglecting its maintenance can lead to:

- Gear damage and noisy operation.

- Reduced engine efficiency.

- Overheating and performance loss.

- Expensive repair costs or complete motor failure.

With a simple maintenance routine, you can prevent these issues and extend the life of your outboard motor.

The Ultimate Lower Unit Maintenance Checklist

1. Regular Gear Oil Checks

Gear oil lubricates the gears in your lower unit, ensuring smooth operation and preventing friction.

- How to Check:

- Remove the drain plug and inspect the oil.

- Look for water contamination (milky appearance) or metal shavings.

- Refill with marine-grade gear oil if needed.

SEO Focus: Always include a gear oil check in your lower unit maintenance checklist.

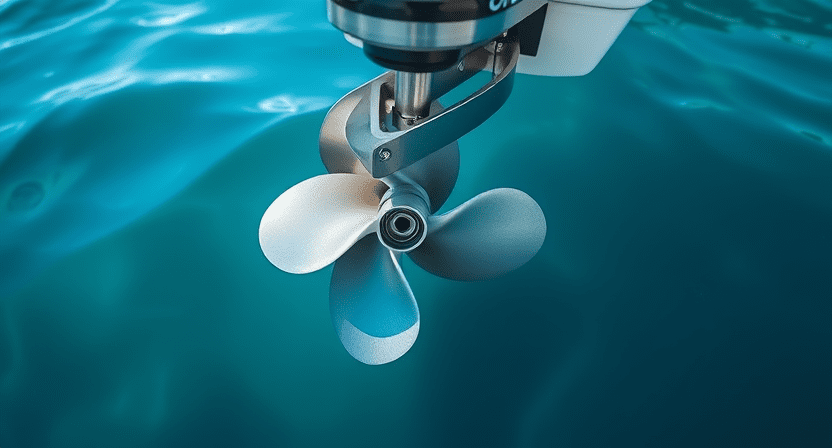

2. Propeller Inspection

A damaged or misaligned propeller can strain the lower unit and reduce efficiency.

- Steps to Inspect:

- Remove the propeller and clean the shaft.

- Look for cracks, dents, or fishing lines wrapped around the shaft.

- Grease the propeller shaft before reinstalling the propeller.

Pro Tip: Check the propeller every time you return from the water.

3. Flush the Lower Unit After Each Use

Saltwater, sand, and debris can accumulate in the cooling system, causing corrosion and blockages.

- How to Flush:

- Attach a flushing device to the motor’s water intake.

- Run fresh water for 5–10 minutes.

- Inspect the water flow to ensure it’s clear.

4. Inspect Seals and Gaskets

Seals and gaskets keep water out of the lower unit. Over time, they can wear out, leading to water intrusion.

- What to Check:

- Propeller shaft seals.

- Driveshaft seals.

- Drain plug gaskets.

Tip: Replace damaged seals immediately to prevent long-term damage.

5. Replace the Impeller Annually

The impeller is a small but critical component that pumps water through the cooling system.

- When to Replace: Every 100 operating hours or once a year.

- How to Check:

- Remove the lower unit and inspect the impeller for cracks or wear.

SEO Focus: Regular impeller replacement is essential for any lower unit maintenance checklist.

Common Signs of Lower Unit Issues

1. Water in the Gear Oil

If the gear oil appears milky, it indicates water intrusion. This usually points to a failed seal.

2. Unusual Noises

Grinding or whining noises often signal gear or bearing problems.

3. Reduced Water Flow

Low water flow from the tell-tale outlet may indicate a clogged water pump or damaged impeller.

Preventing Lower Unit Damage

1. Avoid Shallow Waters

Running your motor in shallow water increases the risk of hitting debris and damaging the propeller or lower unit.

2. Store Your Boat Properly

- Keep the motor tilted down to prevent water from freezing inside the lower unit.

- Use a motor cover to protect against moisture and dust.

3. Follow a Routine Maintenance Schedule

Busy boaters should schedule time every month for basic maintenance tasks, such as gear oil checks and propeller inspections.

Real-World Example

Case Study:

Jake, a weekend boater, neglected his lower unit maintenance checklist for several months. On a fishing trip, he noticed grinding noises and difficulty shifting gears. An inspection revealed water in the gear oil due to a failed seal. After replacing the seal and flushing the unit, the issue was resolved. Jake now follows a monthly maintenance checklist to avoid similar problems.

FAQs About Lower Unit Maintenance

Q1: How often should I check my lower unit gear oil?

Inspect the gear oil every 50 hours of operation or at least once a month.

Q2: Can I perform lower unit maintenance myself?

Yes, many tasks like gear oil checks and propeller inspections can be done at home. For complex repairs, consult a professional.

Q3: How do I know if my lower unit needs repair?

Signs include water in the gear oil, unusual noises, and reduced engine performance.

Conclusion

A well-maintained outboard lower unit ensures your boat performs efficiently and reliably. Following this lower unit maintenance checklist for busy boaters will save you time, money, and frustration in the long run. Regular inspections, cleaning, and timely repairs are key to keeping your boat ready for every adventure.