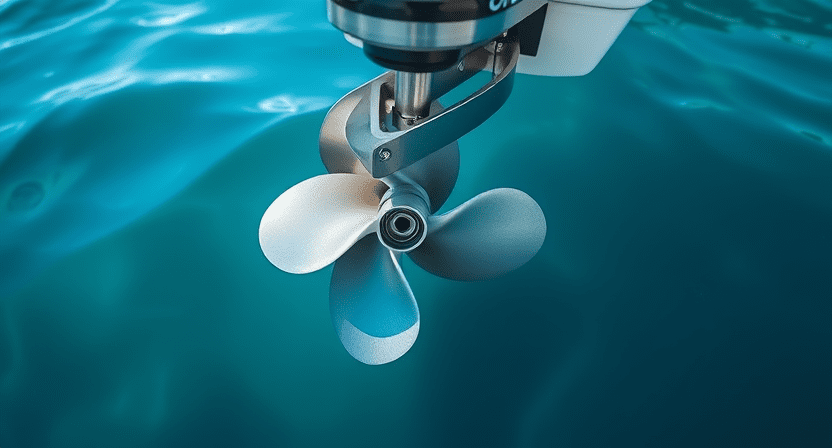

Propeller Durability in Extreme Conditions

When operating a boat in challenging environments, the durability of your propeller plays a critical role. Saltwater and sand are two of the most damaging conditions for marine equipment, particularly for outboard lower units and propellers. This guide explores the best materials, maintenance practices, and real-world advice to ensure your propeller stands up to these extreme conditions.

Why Propeller Durability Matters

Boat propellers are subjected to constant wear and tear, especially in environments where saltwater corrosion and abrasive sand particles are prevalent. A durable propeller ensures optimal performance, fuel efficiency, and reduced long-term costs. Understanding how your propeller interacts with these elements is essential for selecting the right one.

Effects of Saltwater on Propellers

Corrosion Challenges in Saltwater

Saltwater is highly corrosive due to its high salt content and ability to facilitate electrochemical reactions. This can lead to:

- Pitting corrosion on metal propellers.

- Decreased lifespan of the outboard lower unit.

- Weakened structural integrity, leading to cracks or breaks.

Best Materials for Saltwater Propellers

To combat corrosion, consider these materials:

- Stainless Steel: Highly resistant to rust and offers superior strength, making it ideal for saltwater use.

- Aluminum with Protective Coating: While more affordable, these propellers require anti-corrosion coatings to withstand saltwater.

- Composite Materials: Lightweight and corrosion-resistant, composites are a growing choice for saltwater conditions.

The Impact of Sand on Propellers

Abrasive Damage from Sand

Boating in shallow waters or near beaches exposes propellers to sand. This abrasive material can:

- Cause blade erosion, reducing efficiency.

- Scratch the surface, making the propeller vulnerable to corrosion.

- Damage the outboard lower unit, particularly seals and bearings.

Sand-Resistant Design Features

Look for these design elements to ensure durability:

- Thicker Blades: For better resistance to wear.

- Hydrophobic Coatings: Minimize the adhesion of sand and debris.

- Enclosed Propeller Guards: Prevent direct contact with sand.

Maintenance Tips for Extreme Conditions

Regular Cleaning

After every trip, especially in saltwater or sandy areas, rinse your propeller and outboard lower unit with fresh water. This removes corrosive salt deposits and abrasive sand particles.

Inspect for Damage

- Check for dents or cracks in the blades.

- Examine the hub and seals for signs of wear.

- Ensure the outboard lower unit is free from debris.

Lubrication and Anti-Corrosion Products

- Use marine-grade grease on moving parts.

- Apply anti-corrosion sprays to metal surfaces to prevent rust.

Selecting the Right Propeller for Extreme Conditions

Blade Material Matters

Choose a propeller based on your specific environment:

- For saltwater: Opt for stainless steel or composite materials.

- For sandy areas: Consider propellers with reinforced edges or protective coatings.

Pitch and Diameter Considerations

- Higher pitch propellers reduce strain in abrasive environments.

- A larger diameter provides better thrust in sandy or shallow waters.

Real-World Examples of Durable Propellers

Stainless Steel in Saltwater Fishing

Many offshore anglers prefer stainless steel propellers due to their ability to resist corrosion during prolonged exposure to saltwater.

Composite Propellers for Shallow Waters

Boaters navigating sandy rivers often opt for composite propellers, which are lightweight and less likely to sustain damage from sand.

Conclusion

Ensuring propeller durability in extreme conditions like saltwater and sand is vital for safe and efficient boating. By selecting the right materials, implementing regular maintenance, and choosing designs suited for your environment, you can extend the life of your propeller and protect your outboard lower unit. Investing in durability today prevents costly repairs tomorrow.

For more insights, check out our previous blog: Hull Shield Protection in Icy Waters.