What Safety Measures Should You Consider for Lower Units?

For expert advice and high-quality lower units designed to withstand water pressure, visit AllBoatSupplies.com and find the perfect solution for your boat today!

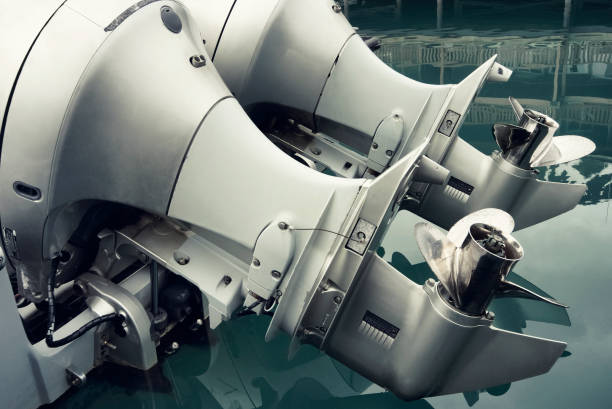

The lower unit of a boat is a critical component that demands careful attention for both performance and safety. Neglecting safety precautions can lead to costly repairs, decreased efficiency, and even dangerous accidents. Whether you’re a seasoned boater or a beginner, understanding and implementing proper safety measures for your lower unit is essential for safe and enjoyable boating. In this comprehensive guide, we’ll walk you through the safety practices every boat owner should follow.

Why Safety Measures for Lower Units Are Important

A boat’s lower unit is directly responsible for transmitting engine power to the propeller, enabling movement. However, damage, improper maintenance, or neglect can compromise its performance, leading to:

- Mechanical Failures: Worn gears or damaged components can cause breakdowns in the middle of your trip.

- Safety Risks: A malfunctioning lower unit can lead to accidents, especially in high-speed or rough waters.

- Increased Costs: Neglecting safety increases the likelihood of expensive repairs or complete replacements.

By prioritizing safety, you not only protect your lower unit but also ensure a secure and worry-free boating experience.

Top Safety Measures for Lower Units

1. Regular Inspections and Maintenance

- Check for Leaks: A leaking gearcase is a clear sign that seals are damaged or worn out. Leaks can allow water to enter, reducing lubrication and causing component failure.

- Inspect for Corrosion: Saltwater environments can cause corrosion, leading to structural weaknesses. Clean and apply anti-corrosion treatments regularly.

- Monitor Propeller Damage: Chips, dents, or bent blades on the propeller can affect the lower unit’s performance and create vibrations that damage internal gears.

2. Use the Correct Lubricants

Always use manufacturer-recommended gear oils for your lower unit. Improper or low-quality oils can reduce lubrication, leading to increased friction and gear wear.

- Change the lubricant periodically to avoid contamination from water or debris.

- Look for milky or cloudy oil during changes, which indicates water intrusion.

3. Protect Seals and O-Rings

The seals and O-rings in a lower unit play a vital role in preventing water ingress and maintaining internal pressure.

- Inspect seals regularly for cracks, wear, or displacement.

- Replace worn seals immediately to avoid larger mechanical issues.

4. Avoid Grounding the Lower Unit

Collisions with underwater obstacles, such as rocks, debris, or sandbars, are a common cause of lower unit damage.

- Stay Vigilant: Use depth finders and follow marked navigation channels to avoid shallow areas.

- Install a Skeg Guard: A skeg guard can provide additional protection against accidental impacts.

5. Winterize Your Lower Unit

If you store your boat during the off-season, ensure proper winterization:

- Drain all water from the lower unit to prevent freezing and cracking.

- Remove and inspect the propeller for fishing line or debris that could damage seals.

- Store the boat in a dry and controlled environment to avoid corrosion.

Common Mistakes to Avoid

1. Ignoring Strange Noises

Grinding, whining, or unusual noises often indicate internal issues, such as worn gears or misaligned components. Ignoring these sounds can lead to bigger problems.

2. Skipping Professional Servicing

While DIY maintenance is essential, certain tasks, such as pressure testing the gearcase or aligning components, require professional expertise.

3. Overloading the Boat

Excessive weight increases strain on the lower unit, leading to overheating and accelerated wear. Always adhere to your boat’s recommended weight capacity.

Additional Tips for Safety

1. Install a Lanyard Cut-Off Switch

This safety feature shuts off the engine if the operator is ejected from the boat, preventing the propeller from causing harm.

2. Carry Emergency Tools

Keep tools on board for basic maintenance and emergency repairs. Include spare seals, lubricants, and a propeller wrench in your toolkit.

3. Train for Emergency Situations

Ensure all operators are trained in handling lower unit failures, such as using auxiliary power or signaling for assistance in case of breakdowns.

Signs That Your Lower Unit Needs Immediate Attention

- Water Intrusion: Presence of water in the gear oil.

- Overheating: Excessive heat during operation, often caused by insufficient lubrication.

- Vibrations: Unusual vibrations could indicate propeller damage or alignment issues.

- Reduced Performance: If the boat struggles to achieve normal speeds or consumes more fuel than usual, inspect the lower unit.

Invest in Preventative Safety Measures

1. Use Propeller Guards

Propeller guards protect the lower unit from damage caused by underwater debris and reduce the risk of injury to swimmers.

2. Upgrade to Modern Lower Units

Newer models often include features like anti-corrosion coatings, enhanced seals, and better hydrodynamics for safer operation.

Benefits of Implementing Safety Measures

- Improved Lifespan: Proper care reduces wear and tear, extending the lower unit’s life.

- Enhanced Performance: A well-maintained lower unit ensures smoother and safer rides.

- Cost Savings: Preventative measures reduce the likelihood of costly repairs or replacements.

- Peace of Mind: Knowing your boat is safe allows you to enjoy the water without worry.

Conclusion

Safety measures for lower units are not just an optional step—they are essential for performance, efficiency, and security on the water. By following these guidelines, you can prevent accidents, save on repairs, and enjoy a seamless boating experience. Regular inspections, proper maintenance, and vigilance are your best tools for ensuring the longevity and safety of your lower unit.