Common Issues with Outboard Lower Units

Common Issues with Outboard Lower Units

The common issues with outboard lower unit are containing some crucial part of any boat’s engine system, responsible for transmitting power from the engine to the propellers, which propel your boat forward. While outboard lower units are designed for durability and reliability, they are not immune to wear and tear. Over time, you may encounter common issues that can affect the performance of the unit, ranging from minor problems to more significant mechanical failures.

This blog will guide you through troubleshooting common issues with your outboard lower unit, including how to diagnose problems, fix minor issues, and know when to seek professional help. We will also touch upon the importance of maintaining related components like the propellers for smooth operation.

Identifying Common Issues with Outboard Lower Units

1. Oil Leaks in the Lower Unit

One of the most common issues with an outboard lower unit is oil leakage. Leaks can occur around the seals, gear case, or other parts of the lower unit. Oil leaks can be problematic, as they may lead to improper lubrication, which increases the risk of internal damage.

How to Troubleshoot:

- Visual Inspection: Start by visually inspecting the lower unit for signs of oil around the seals or gear case.

- Check the Gear Oil: If you notice oil on the surface, check the gear oil level to ensure it is not too low. Low oil levels could indicate a leak.

- Tighten Seals and Bolts: Ensure that the seals and bolts are properly tightened to prevent leakage.

Fix:

If you find a leak, replace the damaged seal or gasket, and refill the lower unit with the appropriate gear oil. If the problem persists, it may require a more in-depth inspection by a professional.

2. Overheating Lower Unit

Overheating is another common issue that can cause significant damage to your outboard lower unit. An overheating motor can lead to performance loss and costly repairs if left unaddressed.

How to Troubleshoot:

- Check Water Flow: Ensure that the water pump is functioning correctly. A clogged water intake or a malfunctioning pump can restrict water flow, leading to overheating.

- Inspect the Impeller: The impeller is responsible for pumping water through the system. A damaged impeller may fail to cool the engine effectively.

Fix:

If you suspect overheating, inspect the water pump and impeller. Clean any debris that may be blocking the water intake and replace the impeller if necessary. Regularly cleaning the cooling system helps maintain optimal performance.

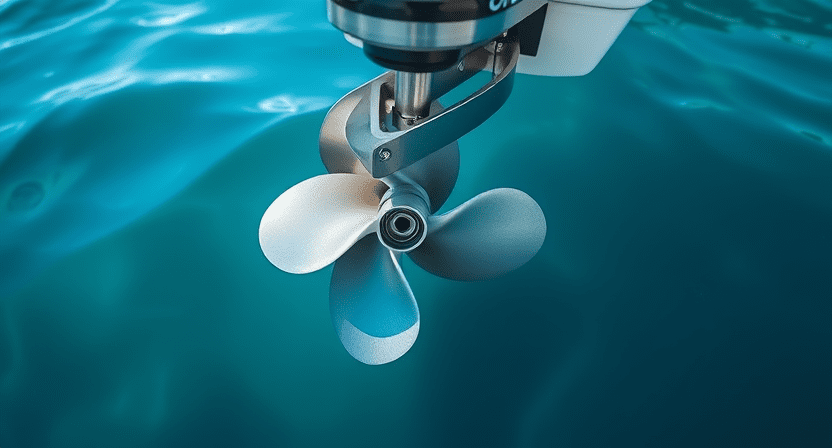

3. Propeller Damage

The propeller is a critical part of the propulsion system, and damage to the propeller can result in poor boat performance. Dings, cracks, or bent blades can cause your boat to slow down, use more fuel, or cause vibrations during operation.

How to Troubleshoot:

- Visual Inspection: Inspect the propeller for any visible signs of damage, including cracks, chips, or bent blades.

- Check for Vibration: When the boat is in motion, vibrations may indicate a misaligned or damaged propeller.

Fix:

Replace or repair any damaged propeller blades. If the damage is minor, professional propeller repair services may be able to restore the propeller to its original condition.

4. Low or No Thrust

If your boat isn’t moving as fast as it should, or if it’s struggling to gain speed, it could be due to an issue with the outboard lower unit, such as a worn propeller or malfunctioning gears.

How to Troubleshoot:

- Check the Propeller: A damaged or incorrectly pitched propeller may not generate sufficient thrust. Ensure that the propeller is in good condition and properly installed.

- Inspect the Gears: The gears in the lower unit transfer power to the propeller. If they are worn or damaged, they may fail to generate sufficient thrust.

Fix:

If the propeller and gears are in good condition, the issue may be related to improper alignment or low oil levels. Regular maintenance and proper gear oil changes can help prevent low thrust problems.

5. Excessive Noise

Unusual or excessive noise coming from the outboard motor is often a sign of an underlying issue. Grinding, clunking, or squealing noises can indicate a problem with the lower unit, such as damaged gears or insufficient lubrication.

How to Troubleshoot:

- Listen for Noise Patterns: Pay attention to the type of noise—grinding typically indicates a gear problem, while squealing may suggest a lack of lubrication or a misaligned shaft.

- Check Oil Levels: Ensure that the oil levels are adequate, as low or dirty oil can lead to poor lubrication and cause noisy operation.

Fix:

If you notice excessive noise, check the oil levels and replace it if necessary. If the noise persists, inspect the gears and bearings for signs of wear and damage. A professional technician may be needed if the problem is internal.

Preventive Maintenance for Your Outboard Lower Unit

While troubleshooting can help identify and fix issues, preventive maintenance is key to avoiding future problems with your outboard lower unit. Here are some important steps you can take to keep your lower unit in good condition:

- Regular Oil Changes: Change the gear oil in your outboard lower unit at least once a year, or more frequently if you use your boat often. Fresh oil ensures smooth gear operation and prevents rust and corrosion.

- Clean the Water Pump: Clean the water pump and intake screens regularly to ensure proper cooling.

- Inspect Propellers: Frequently inspect the propeller for damage, and ensure it is properly aligned to avoid issues with thrust and efficiency.

- Store Your Boat Properly: When not in use, store your boat in a dry, cool place. Ensure that the lower unit is free from water to prevent internal damage from freezing.

Conclusion: Keep Your Outboard Lower Unit in Top Shape

Regular inspection and maintenance of your outboard lower unit are crucial for avoiding costly repairs and ensuring that your boat runs smoothly. Whether you are dealing with oil leaks, overheating, propeller damage, or other issues, understanding how to troubleshoot common problems is an essential skill for any boat owner.

By performing regular maintenance and addressing issues early, you can enjoy years of reliable boating without the worry of unexpected breakdowns. Stay proactive and maintain your outboard lower unit to ensure smooth sailing every time you hit the water.

Tags:

outboard motor issues, outboard lower unit, propeller maintenance, troubleshooting boat issues, outboard motor care, lower unit problems, boat maintenance, boating tips, gear oil change, propeller inspection

You can also learn about our previous blog How to Inspect and Maintain Your Hull Shield.