Ultimate Guide to Outboard Lower Unit Troubleshooting

Ultimate Guide to Outboard Lower Unit Troubleshooting

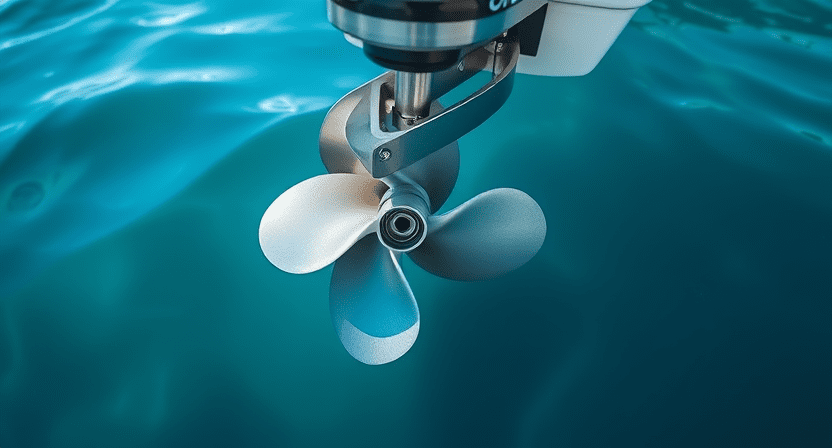

When your outboard motor isn’t performing as expected, the outboard lower unit is often the culprit. This critical component contains the gears, propeller shaft, and water pump that ensure your motor operates smoothly. Learning how to Outboard lower unit troubleshooting problems can save you time, money, and frustration.

Outboard lower unit troubleshooting guide will help you identify and resolve common lower unit issues. Whether you’re dealing with unusual noises, shifting problems, or propeller damage, we’ve got you covered.

Understanding the Outboard Lower Unit

The lower unit is the bottom section of your outboard motor. It houses several essential components:

- Propeller: Drives the boat forward or backward.

- Gearbox: Controls shifting and power transfer.

- Water Pump: Cools the engine.

Regular maintenance and proper troubleshooting are key to avoiding costly repairs.

Common Signs of Lower Unit Problems

1. Unusual Noises

Whining, grinding, or clunking noises often indicate worn gears or insufficient lubrication.

Solution: Check the gear oil levels and look for signs of contamination or metal shavings.

2. Difficulty Shifting Gears

If the motor struggles to shift between forward, neutral, and reverse, the issue may lie in the gear linkage or cables.

Solution: Inspect the cables for wear and adjust them as needed.

3. Propeller Vibration

Excessive vibration can result from a bent propeller shaft or damaged propeller.

Solution: Remove the propeller and inspect it for cracks, dings, or misalignment.

4. Water Intrusion in Gear Oil

Milky or foamy gear oil is a sign of water intrusion, often caused by a failed seal.

Solution: Replace the seals and refill the gear oil.

Steps to Troubleshoot Outboard Lower Unit Issues

1. Inspect the Gear Oil

- Drain the lower unit’s gear oil into a clear container.

- Look for discoloration, water contamination, or metal shavings.

- Replace the oil with marine-grade lubricant if needed.

Pro Tip: Change the gear oil every 100 hours of operation or at least once a year.

2. Check the Propeller

- Remove the propeller and inspect for damage.

- Ensure the propeller shaft isn’t bent.

- Grease the shaft before reinstalling the propeller to prevent rust and corrosion.

SEO Focus: Fixing outboard propeller problems starts with regular inspections.

3. Test the Water Pump

- Inspect the water intake screens for debris.

- Check the impeller for wear and tear. Replace it annually to ensure proper cooling.

- Look for blockages in the cooling passages.

4. Examine the Gear Linkage

- Disconnect the cables and manually shift the gears.

- If shifting improves, the cables may need adjustment or replacement.

Pro Tip: Use a service manual specific to your motor for cable adjustment guidelines.

5. Address Seal Failures

Seals prevent water from entering the lower unit. Common seals to check include:

- Propeller shaft seals.

- Driveshaft seals.

- Shift rod seals.

Replace any damaged or worn seals promptly.

Preventing Lower Unit Failure

Preventive maintenance is the best way to avoid lower unit problems. Here’s what you can do:

- Flush the engine with fresh water after every use to remove salt and debris.

- Check the gear oil regularly and replace it as recommended.

- Avoid running the propeller in shallow water to prevent damage.

- Schedule annual inspections with a certified technician.

Real-World Example

Case Study:

Mike, a boat owner, noticed a grinding noise while shifting gears. Upon inspection, he found water in the gear oil due to a failed seal. After replacing the seal and refilling the oil, the issue was resolved. Regular maintenance could have prevented the problem.

FAQs

Q1: How do I know if my lower unit needs repair?

Look for signs like water in the gear oil, difficulty shifting, or unusual noises.

Q2: How often should I inspect my propeller?

Inspect the propeller before and after every trip, especially if you’ve traveled through shallow or debris-filled water.

Q3: Can I repair the lower unit myself?

Basic tasks like replacing seals or checking the oil can be done at home. For complex issues, consult a professional.

Conclusion

Proper troubleshooting of your outboard lower unit ensures your motor stays in top condition. Regular inspections, timely repairs, and preventive maintenance can help you avoid costly breakdowns. With these tips, you’ll be better equipped to keep your boat running smoothly and safely.