Understanding an Outboard Lower Unit Maintenance

What Is an Outboard Lower Unit maintenance?

Essentially, an Outboard Lower Unit maintenance is the powerhouse of the motor, playing a crucial role in transferring engine power to the propellers. It consists of several essential components that work together to propel your boat efficiently and reliably. For this reason, understanding its functionality is key to ensuring optimal performance and longevity of your outboard motor in this guide you will learn about Outboard Lower Unit maintenance.

Components of an Outboard Lower Unit

-

Gearbox

Specifically, the gearbox houses gears that transfer power from the engine to the propeller shaft. As a result, it allows the propeller to rotate in forward, neutral, or reverse directions.

-

Drive Shaft

This component connects the engine to the gearbox. Consequently, it transfers the engine’s rotational force to the gears within the lower unit.

-

Propeller Shaft

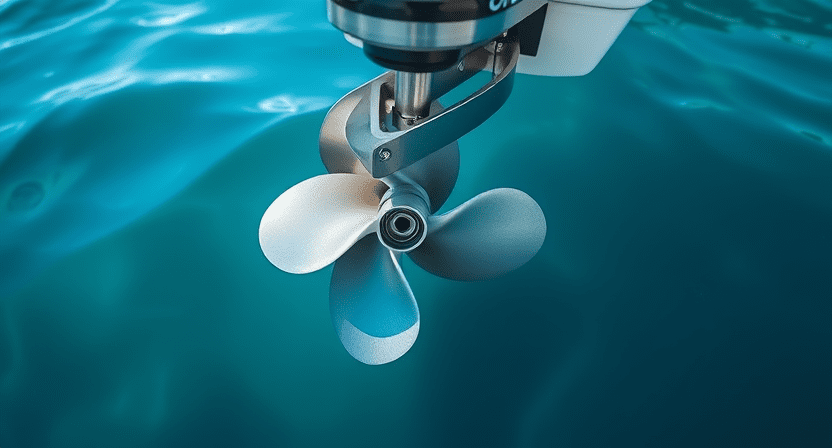

The propeller shaft is connected to the gearbox and directly drives the propellers, creating the thrust needed to move the boat.

-

Water Pump

The water pump, located in the lower unit, is essential for cooling the engine. It circulates water through the cooling system, preventing overheating.

-

Casing

The lower unit’s casing protects internal components from water damage, debris, and corrosion. Additionally, it is typically designed to streamline water flow for better efficiency.

How an Outboard’s Lower Unit Works

When the engine runs, the drive shaft transfers rotational energy to the gearbox in the lower unit. The gearbox then adjusts the direction of rotation based on the gear selected (forward, neutral, or reverse). This rotational force is passed to the propeller shaft, which spins the propellers to propel the boat. Simultaneously, the water pump circulates water to keep the engine cool.

Importance of Proper Maintenance

Therefore, maintaining the lower unit is vital to avoid costly repairs and ensure smooth operation. Here are essential maintenance tips:

-

Check and Change Gear Oil Regularly

Additionally, gear oil lubricates the moving parts inside the gearbox. Thus, it’s important to replace it at least once a season to prevent wear and tear.

-

Inspect for Leaks

A leaking lower unit can lead to water intrusion, damaging the gears and bearings. Therefore, regularly check for oil leaks and repair them promptly.

-

Examine the Propellers

Damaged propellers can cause vibrations and reduce efficiency. As a result, remove the propellers periodically to check for fishing lines or debris.

-

Flush the Water Pump

After every use, especially in saltwater, flush the water pump to remove debris and salt deposits.

-

Replace Seals and Gaskets

Over time, seals and gaskets may wear out. Therefore, replace them during routine maintenance to prevent water ingress.

Practical Tips for Optimal Performance

-

Choose the Right Propellers

The type and size of propellers directly impact your boat’s speed and fuel efficiency. Consequently, consult your manufacturer’s recommendations for the best fit.

-

Avoid Running Aground

For instance, running aground can damage the lower unit’s casing and propellers. Always navigate carefully in shallow waters to avoid this issue.

-

Winterize Your Outboard

If you store your boat during the off-season, winterize the lower unit by draining the gear oil and inspecting the water pump.

-

Monitor Noise and Vibrations

Unusual noises or vibrations can indicate lower unit issues. As a result, address these symptoms early to prevent further damage.

Common Issues and Troubleshooting

-

Gear Slippage

If the gears slip, it may indicate worn-out components or improper alignment. In this case, seek professional help to fix this issue.

-

Overheating

An overheated engine could result from a faulty water pump or clogged water intake. Therefore, inspect and clean these components regularly.

-

Loss of Thrust

If the boat loses thrust, check the propellers for damage or obstructions.

Why the Lower Unit Matters

The lower unit is integral to your outboard motor’s performance. A well-maintained lower unit ensures smooth operation, fuel efficiency, and a longer lifespan for your outboard motor. Understanding its components and functions empowers boat owners to troubleshoot issues effectively and enjoy hassle-free boating.

Conclusion

The outboard’s lower unit is the backbone of your motor’s functionality. By understanding its workings and following proper maintenance practices, you can enhance your boating experience while avoiding unnecessary repairs. Whether you’re a beginner or an experienced boater, investing time in lower unit care will pay off in the long run.