What is an Outboard Lower Unit and How It Works

Introduction

The outboard lower unit is a critical part of your boat’s engine, responsible for transferring power from the motor to the propeller. Understanding how it works and its role in your boat’s performance is essential for every boat owner. In this guide, we’ll break down the mechanics of an outboard lower unit, explore its components, and explain why its maintenance is crucial.

Whether you’re a boating enthusiast or a first-time owner, this guide will give you a clear understanding of the outboard lower unit and how it powers your marine adventures.

What Is an Outboard Lower Unit?

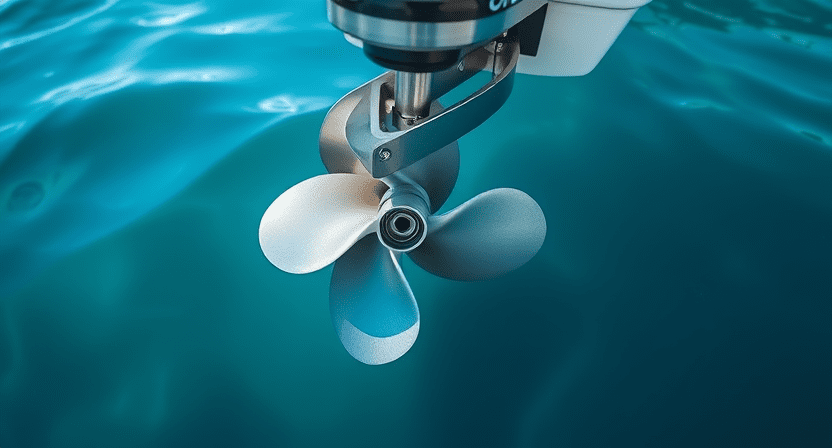

The outboard lower unit is the underwater portion of your outboard motor. It houses gears, shafts, and other components that work together to convert the engine’s power into rotational force for the propeller.

Key Functions of the Lower Unit:

- Power Transfer: Transmits power from the engine to the propeller.

- Gear Reduction: Adjusts the engine’s speed to optimize propeller rotation.

- Directional Control: Allows the boat to move forward or reverse.

Components of an Outboard Lower Unit

Understanding the parts of the lower unit helps you grasp how it works and why regular maintenance is vital.

1. Drive Shaft

The drive shaft connects the engine to the lower unit, delivering rotational force to the gears.

2. Gears

The gears (forward, neutral, and reverse) determine the propeller’s direction of rotation.

3. Propeller Shaft

The propeller shaft transfers the gears’ rotation to the propeller.

4. Water Pump

Located in the lower unit, the water pump cools the engine by circulating water through it.

5. Oil Reservoir

Marine-grade gear oil lubricates the internal components, reducing friction and preventing wear.

Pro Tip: Familiarize yourself with these parts to better understand maintenance tasks like oil changes and seal inspections.

How Does an Outboard Lower Unit Work?

The outboard lower unit works through a series of mechanical processes that ensure smooth propulsion.

Step-by-Step Process:

- Power Transmission: The engine sends rotational force down the drive shaft.

- Gear Engagement: The gears within the lower unit adjust to the selected mode (forward, neutral, or reverse).

- Propeller Rotation: The propeller shaft transfers the gears’ motion to the propeller, creating thrust.

- Cooling System: The water pump prevents overheating by drawing water from outside the boat and circulating it through the engine.

Why Is Maintenance of the Lower Unit Important?

Proper care of the outboard lower unit ensures its longevity and optimal performance. Neglecting maintenance can lead to serious issues like gear damage or water intrusion.

Benefits of Regular Maintenance:

- Improved Performance: Clean oil and well-maintained parts reduce friction and enhance efficiency.

- Cost Savings: Prevents costly repairs caused by neglected issues.

- Safety: A well-maintained lower unit ensures reliable operation on the water.

Common Problems with Outboard Lower Units

- Water Contamination: Caused by damaged seals, leading to corrosion and poor lubrication.

- Gear Damage: Due to inadequate lubrication or debris in the oil.

- Propeller Issues: Damaged propellers can cause vibrations and stress the lower unit.

Pro Tip: Address these issues immediately to prevent further damage.

How to Maintain an Outboard Lower Unit

1. Regular Oil Changes

- Replace the gear oil every 100 hours of operation or annually.

- Use marine-grade oil to protect against moisture.

2. Inspect Seals and Gaskets

- Check for leaks or damage during each oil change.

- Replace worn gaskets to prevent water intrusion.

3. Propeller Maintenance

- Remove the propeller periodically to check for fishing lines or debris.

- Grease the propeller shaft to prevent rust.

4. Monitor for Noise or Vibrations

Unusual noises or vibrations may indicate gear or propeller problems. Investigate and resolve these promptly.

Real-World Example

A boater once noticed a milky appearance in their lower unit oil, a clear sign of water contamination. Upon inspection, they found a damaged seal. Timely replacement of the seal and an oil change saved the gears from extensive damage, costing only a fraction of what a full repair would have required.

Conclusion

Understanding the outboard lower unit and how it works is essential for every boat owner. By grasping its components, role, and maintenance requirements, you can ensure your motor runs smoothly and efficiently. Regular maintenance not only protects your investment but also guarantees safety and performance on the water.

Take care of your outboard lower unit, and it will reward you with reliable operation for years to come.