Why Outboard motor lower unit oil Maintenance Is Essential

Introduction

Taking care of your outboard motor lower unit oil is vital for the health and longevity of your boat’s engine. Neglecting this simple task can lead to expensive repairs, loss of performance, or even engine failure. This guide explores why maintaining your outboard lower unit is essential, explains the process in detail, and provides actionable tips for both seasoned and beginner boat owners.

Understanding the Outboard Motor Lower Unit

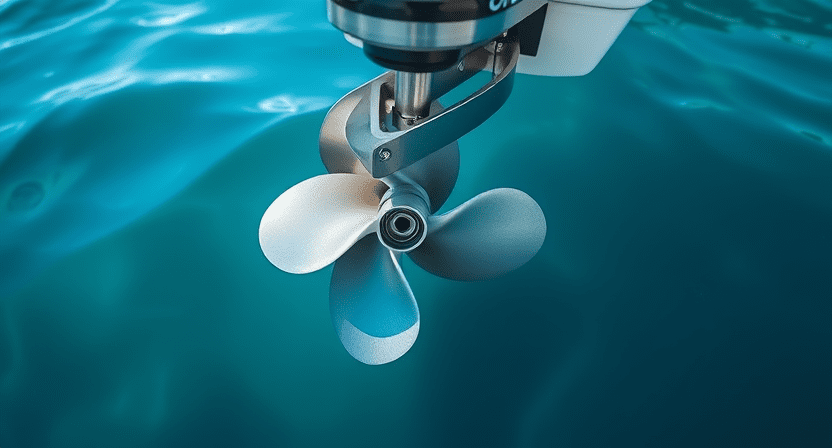

The lower unit of your outboard motor houses critical components like gears, shafts, bearings, and the propeller. It converts the engine’s power into movement, propelling your boat forward.

Lower unit oil plays a pivotal role in this process, ensuring all components are well-lubricated and protected from wear, corrosion, and contamination. Regular maintenance ensures optimal performance and prevents damage.

Why Regular Maintenance of Lower Unit Oil Is Crucial

1. Prevents Corrosion and Rust

Water intrusion can lead to corrosion in the lower unit. Regular oil changes prevent this by removing moisture and keeping components protected.

2. Ensures Proper Lubrication

Lubrication reduces friction between moving parts. Without clean oil, the gears and bearings in the lower unit can overheat and wear out prematurely.

3. Avoids Costly Repairs

Contaminated oil can damage the gears and propeller shaft. Regular maintenance can identify problems early, saving you from expensive repairs.

4. Improves Performance

Clean lower unit oil ensures smooth operation, better fuel efficiency, and consistent power delivery.

Signs Your Outboard Motor Lower Unit Oil Needs Attention

- Milky or Discolored Oil: Indicates water contamination.

- Metal Shavings: Found in drained oil, suggesting gear damage.

- Unusual Noises: A sign of improper lubrication.

- Leaking Oil: Indicates worn-out seals or gaskets.

How to Maintain Outboard Motor Lower Unit Oil

1. Regular Oil Changes

- Change the oil every 100 hours of operation or at the end of the season.

- Use marine-grade gear oil for better moisture resistance.

2. Inspect Seals and Gaskets

- Check for wear or damage during each oil change.

- Replace faulty gaskets to prevent leaks.

3. Monitor for Contamination

- Look for water or debris in the oil during changes.

- Address any issues immediately to prevent further damage.

4. Keep the Propeller Shaft Clean

- Remove the propeller regularly to check for fishing lines or debris.

- Grease the shaft to prevent rust.

Step-by-Step Guide to Changing Lower Unit Oil

- Gather Your Tools and Materials

- Marine-grade lower unit oil

- Oil drain pan

- Screwdrivers or socket wrench

- Gear oil pump

- Position Your Motor

- Place the motor in a vertical position to ensure proper drainage.

- Drain the Oil

- Unscrew the drain and vent plugs to allow the oil to flow out.

- Inspect the Drained Oil

- Look for water, debris, or metal shavings.

- Replace the Gaskets

- Install new gaskets on the drain and vent plugs.

- Refill with Fresh Oil

- Use a gear oil pump to refill until oil flows from the vent hole.

- Reinstall the Plugs

- Tighten the plugs securely to prevent leaks.

Common Mistakes to Avoid

1. Skipping Regular Oil Changes

Old oil loses its effectiveness, increasing the risk of damage.

2. Using Incorrect Oil

Always use marine-grade gear oil to protect against water and corrosion.

3. Neglecting Seal Maintenance

Faulty seals can lead to water intrusion and costly repairs.

4. Overlooking Propeller Maintenance

A neglected propeller can cause vibrations, inefficiency, and damage to the lower unit.

Practical Tips for Beginners

- Create a Maintenance Schedule: Track oil changes and inspections.

- Keep Spare Parts Handy: Have extra gaskets and oil on hand.

- Learn to Identify Problems: Understanding common issues helps you take action quickly.

Real-World Example

A recreational boater delayed changing their outboard motor lower unit oil for an entire season. During a routine check, they found water contamination that had damaged the gears. This oversight resulted in a $1,500 repair bill—an expense that could have been avoided with regular maintenance.

Conclusion

Maintaining your outboard motor lower unit oil is essential for protecting your investment and ensuring a smooth boating experience. By following the steps in this guide, you can avoid costly repairs, improve performance, and enjoy worry-free time on the water. Make lower unit maintenance a priority to extend the life of your outboard motor.