Weld Mount SS Stud Best & Worst Cases

Weld Mount 1.00″ Tall 1/4 x 20 ST125-1420-16SS SS Stud 1.25″ Base 10 Pack for Boats & Marine Engines

Introduction

When it comes to marine-grade hardware, nothing beats the reliability and strength of the Weld Mount 1.00″ Tall 1/4 x 20 ST125-1420-16SS SS Stud 1.25″ Base 10 Pack for Boats & Marine Engines. Designed with precision and made from 316 stainless steel, these adhesive-mounted studs are essential for any electrical and lighting installation on your vessel. Ideal for environments that demand corrosion resistance, vibration control, and minimal surface damage, this Weld Mount SS Stud is the perfect fit for high-performance marine applications.

Whether you’re securing panels, routing wiring, or mounting electrical boxes, these studs make installation efficient and durable. In this comprehensive guide, we cover everything from product details to expert tips and frequently asked questions, so you can make an informed buying decision.

Overview / What Is Weld Mount SS Stud

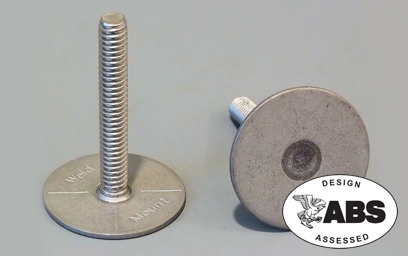

The Weld Mount SS Stud 1.00″ Tall 1/4 x 20 is a threaded stainless steel stud mounted via a high-strength adhesive base. Instead of drilling holes into your boat’s fiberglass or aluminum, you simply bond this stud to the surface using marine-grade adhesive, providing an ultra-strong attachment point without compromising hull integrity.

With a 1.25″ wide base and 1.00″ tall profile, it fits perfectly in tight areas while offering excellent support for wire clamps, brackets, and electrical conduits. The 1/4 x 20 thread pitch is standard across many marine-grade hardware accessories, ensuring compatibility and reliability on both commercial and recreational vessels.

Benefits of Using Weld Mount SS Stud for Marine Applications

Using Weld Mount SS Stud systems onboard boats and marine engines provides a wide range of advantages:

- Corrosion Resistance: Made from 316 stainless steel, this stud resists rust and salt exposure.

- No-Drill Install: Avoid damaging panels and gelcoats with the adhesive-mounted solution.

- Fast Installation: Requires no welding or special tools – just clean, apply adhesive, and press into place.

- Versatility: Ideal for mounting electrical panels, clamps, engines, or accessories securely.

- Vibration Dampening: Adhesive absorbs vibration for enhanced safety and longevity.

Whether you’re doing routine maintenance or upgrading your vessel’s systems, the Weld Mount SS Stud is the go-to choice for installers and boat owners alike.

How to Install Weld Mount SS Stud

One of the most common long-tail questions is how to install Weld Mount SS Stud. The process is simple and does not require specialized training. Follow the steps below:

- Clean the bonding surface with alcohol or acetone to remove oils, dirt, or residues.

- Apply the recommended Weld Mount adhesive (e.g., AT-8040 or AT-4020) to the 1.25″ base of the stud.

- Firmly press the stud onto the surface and hold for 60 seconds. Use tape to secure during cure time if needed.

- Allow the adhesive to fully cure — from 5 minutes (fast-cure adhesives) up to 24 hours for long-term bonding strength.

Once cured, the Weld Mount SS Stud can be torqued down with accessories or used as a threaded anchor for heavier installations.

Typical Use Cases on Boats & Marine Engines

The design of the Weld Mount SS Stud makes it perfect for a wide variety of marine use cases:

- Wiring Harness Support: Secure your wiring to hulls, cabins, or below deck for neat routing.

- Control Panel Installation: Mount instrument panels or switch boxes without drilling holes.

- Battery and Fuel Clamp Support: Hold large battery or fuel lines in place to reduce movement.

- Seating and Trim Support: Use as discreet anchor points on fiberglass or composite interiors.

Since these are installed without metal-on-metal contact, you avoid galvanic corrosion risks common with dissimilar metal contact on boats.

Weld Mount SS Stud Cost and Durability Comparison

Compared to traditional hardware, the Weld Mount SS Stud provides long-term savings by minimizing labor, eliminating the need for drill holes, and reducing future repairs. Its 316 stainless steel build ensures high durability in marine environments, especially under high moisture and salt exposure.

Many professional installers find the system cost-effective thanks to time savings on labor. Its durability also means fewer replacements over time. It’s a win for both DIYers and commercial fleet operators.

Maintenance Tips

Though designed for extreme durability, the Weld Mount SS Stud still benefits from regular maintenance checks to ensure longevity and safety:

- Visual Inspection: Check the adhesive area for any lifting, separation, or signs of wear every 3–6 months.

- Clean Surfaces: Keep the area around the stud clean to prevent salt or grime from degrading the adhesive.

- Avoid Over-Torquing: When attaching hardware, do not exceed torque recommendations as it may cause delamination.

Regular upkeep will help ensure that your mounting points stay secure and functional, even in the harshest marine conditions.

Expert Advice and Pro Recommendations

Marine professionals consistently recommend the Weld Mount SS Stud system over conventional methods for boat hardware mounting. Its no-drill design prevents structural weakening of sensitive surfaces like composite panels and fiberglass walls.

Buy now: Weld Mount 1.00″ Tall 1/4 x 20 ST125-1420-16SS SS Stud 1.25″ Base 10 Pack and use the code WELCOME5 to receive 5% off your order. Installation professionals prefer this kit for wiring, plumbing, and engine installations alike, especially when time and durability matter most.

How the Weld Mount SS Stud Compares to Rivet and Bolt Systems

Traditional rivets and bolts require through-hull or panel drilling, introducing risks like water intrusion, corrosion, and reduced structural integrity. In contrast, the Weld Mount SS Stud eliminates these concerns. Its adhesive-bonded base offers equivalent strength without the permanent damage caused by drilling.

Its sleek installation process and proven strength under stress make it a superior solution for mounting electrical or mechanical components on any boat. Yamaha Outboards has also endorsed modern adhesive-based systems for optimized rigging on high-performance vessels.

Detailed FAQ Section

What kind of adhesive should I use with the Weld Mount SS Stud?

For best results, use Weld Mount’s proprietary adhesives such as AT-8040 (fast-set) or AT-4020 (general marine adhesive). These are specifically engineered to bond with fiberglass, metal, and composite materials. Avoid generic glues, as they may not offer the same load-bearing capacity or curing performance.

Can I remove a Weld Mount SS Stud after installation?

Yes, but removal requires heat and proper technique. Use a heat gun to soften the adhesive, then carefully pry off the stud without damaging the substrate. Once removed, clean residual adhesive with a solvent. Avoid forcibly pulling the stud, as that may tear the laminate or surface layer of the panel.

Is the Weld Mount SS Stud suitable for wet or submerged areas?

Yes, the Weld Mount SS Stud can be installed in areas exposed to moisture or intermittent submersion. Ensure that you use marine-grade adhesive rated for wet applications and allow full curing before exposure to water. For permanent underwater use, AT-6030 adhesive is highly recommended.

Can I paint over the Weld Mount SS Stud?

Yes, you can paint over both the base and shaft of the stud using marine-grade paints. Just ensure the surface is primed properly and cured. However, do not paint over adhesive joints during curing, as it could affect adhesion. Painting helps to maintain aesthetics and adds a layer of corrosion resistance.

How strong is the bond of a Weld Mount SS Stud?

When installed correctly, a single Weld Mount SS Stud can hold up to 250 pounds in tensile strength, depending on the adhesive and substrate used. It is vibration-resistant and offers performance comparable to traditional bolting systems, without damaging your boat’s structure.

Conclusion

The Weld Mount 1.00″ Tall 1/4 x 20 ST125-1420-16SS SS Stud 1.25″ Base 10 Pack for Boats & Marine Engines stands out as one of the most efficient, secure, and reliable mounting systems in today’s marine industry. With no need for drilling, high corrosion resistance, and ease of use, it’s ideal for both novice boat owners and seasoned marine professionals. This installation accessory redefines simplicity, strength, and versatility for every boat upgrade or build.

Special Offer

WELCOME5 – Get 5% off storewide at allboatsupplies.com

🚀 Instant Assistance: Need help selecting the right product? Drop your contact in the chatbox at the bottom right corner, and our expert team will reply within 30 minutes with the best product suggestion for your boat — including a ready-to-use checkout link. We’re fast, knowledgeable, and always here for your boating needs!

No more guesswork — just message us and get a personalized checkout link fast!

Let us handle the hassle — expert support, quick replies, and smooth checkout. Your boat deserves the best.

🔥 Up to 5% OFF – Limited Time!

Use code WELCOME5 on Weld Mount 1.00″ Tall 1/4 x 20 ST125-1420-16SS SS Stud 1.25″ Base 10 Pack

🚀 Buy Now – Weld Mount 1.00″ Tall 1/4 x 20 ST125-1420-16SS SS Stud 1.25″ Base 10 Pack